Noblesville, IN (June 25, 2024) – MPP, a leading manufacturer of custom-engineered components, is pleased to announce that it received a Grand Prize Award from the Metal Powder Industries Federation for its development of a core plate within the electrical category for Metal Injection Molding (MIM) components. The core plate is a central component in the Cadence Tablet, the first tactile device able to display tactile graphics that move and change beneath your fingers.

MPIF’s Design Excellence Award competition recognizes distinguished examples of the efforts made in powder metallurgy, metal injection molding, and additive manufacturing to advance new technologies and improve the net shape, precision, product efficiency, and manufacturing cost associated with the design.

Over the last year, MPP and Tactile Engineering, an Indiana-based startup developing advanced assistive technologies, have collaborated on an application allowing the vision impaired to experience an entirely new way to access dynamic content and multi-line braille.

Lack of effective accommodations has been a barrier for vision-impaired people at work, especially in today’s high-demand technical workplaces. Tactile Engineering’s Cadence Tablet hopes to remove this barrier.

Users of the Cadence Tablet can experience a whole new way to access information and dynamic content, including pop-up highlights and labels, graphs that update in real-time, live camera feeds, and fast-paced entertainment apps that rely on their reflexes and sense of touch. This innovative device integrates powerful new tactile dot technology with software and apps, offering capabilities the blind community has awaited for decades.

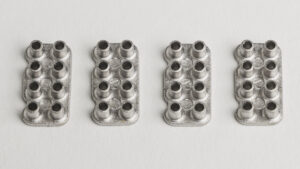

Working together, the MPP technical group and Tactile Engineering team developed a robust process suited for metal injection molding to produce the core plate for the application. This complex part, if not produced to print, would be a single point of failure in the Cadence Braille Tablet, requiring a specific amount of holding forces to operate, strict adherence to tight tolerances, flatness, magnetism, and more.

When evaluating the technology to produce the component, it was determined that MIM provided the best alternative to traditional machining. Metal injection molding provides a robust, scalable solution, especially for a challenging component such as this.

“We chose the MIM process and MPP as our vendor due to the extreme complexity and precise tolerances of this part,” said Dave Schleppenbach, CEO of Tactile Engineering. “After years of R&D to develop the specifications for the part, we determined that the cutting-edge approach offered by MPP was the only viable method of large-scale production of a part this intricate. We are excited to continue our work with MPP to scale up our production process and deliver the vitally important Cadence tactile tablet product to visually-impaired users worldwide.”

“The customer is dependent on the performance of our part for them to be able to succeed in bringing this life-changing technology to the vision impaired. We are incredibly excited and proud about this application that Tactile Engineering will bring to market to improve the quality of life for so many,” said Wiley Abner, VP of Engineering and Quality.