Leading Innovation in Metal Technologies

Shorter Lead Times with American-Made Components

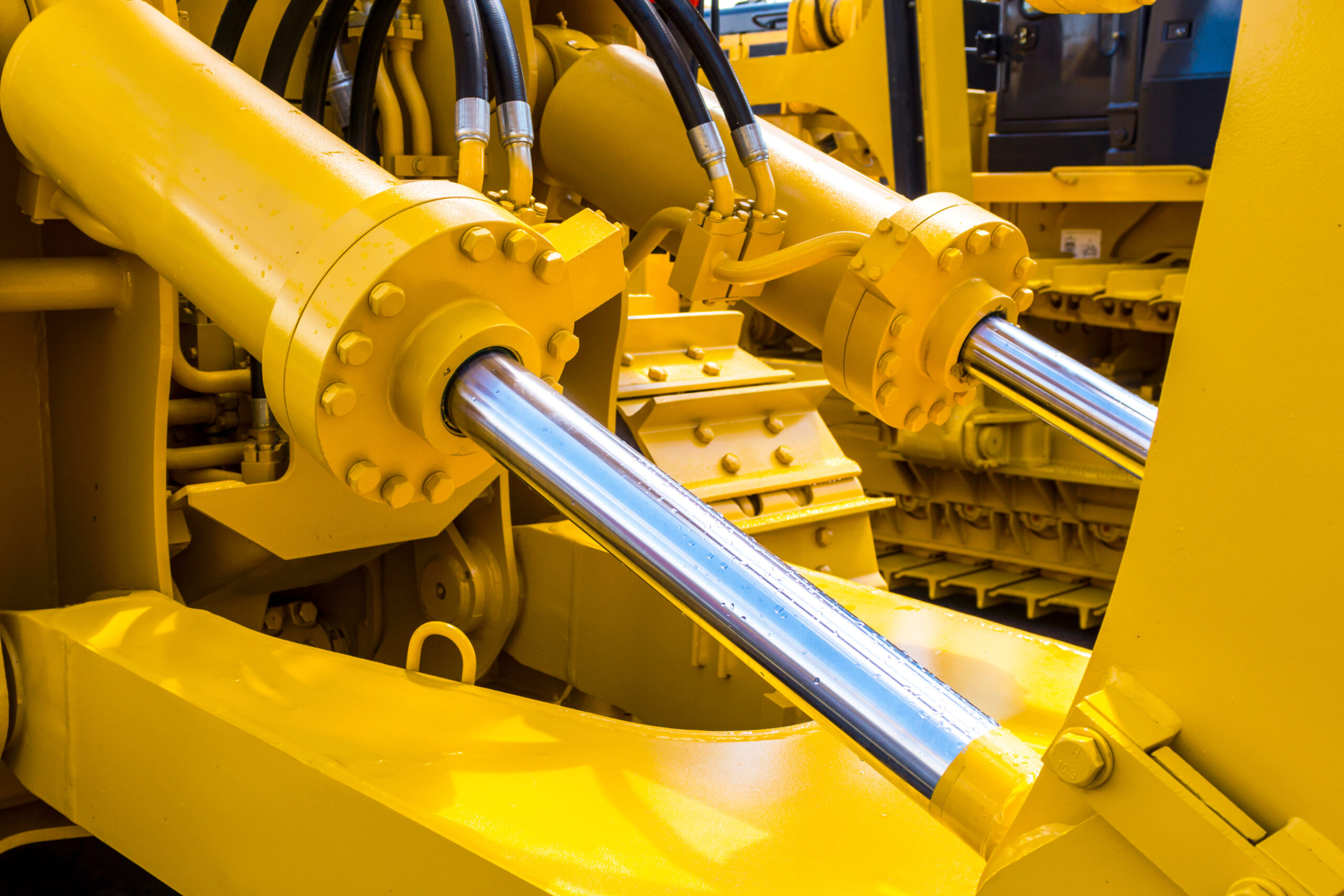

If you're feeling the pressure of tariffs and sourcing challenges, you're not alone. Many manufacturers are beginning to rethink their supply chains to reduce risk and improve reliability.

At MPP, we help businesses build stronger, more reliable supply chains in the U.S. By keeping production stateside, we help manufacturers avoid costly tariffs, minimize delays, and ensure a steady supply of high-quality components.

Your Engineering Team: Partners in Innovation

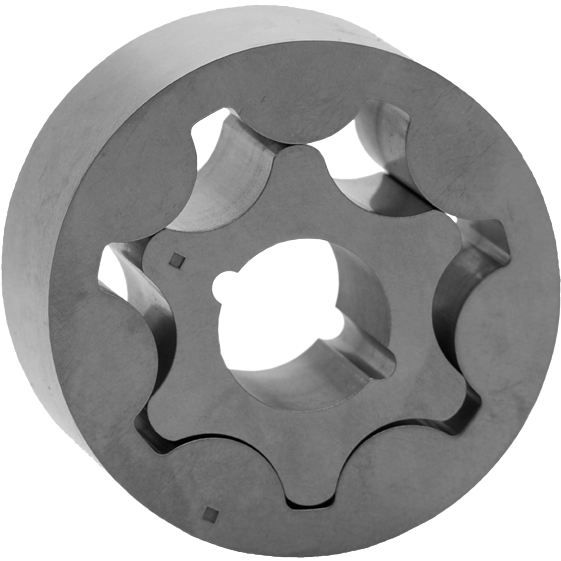

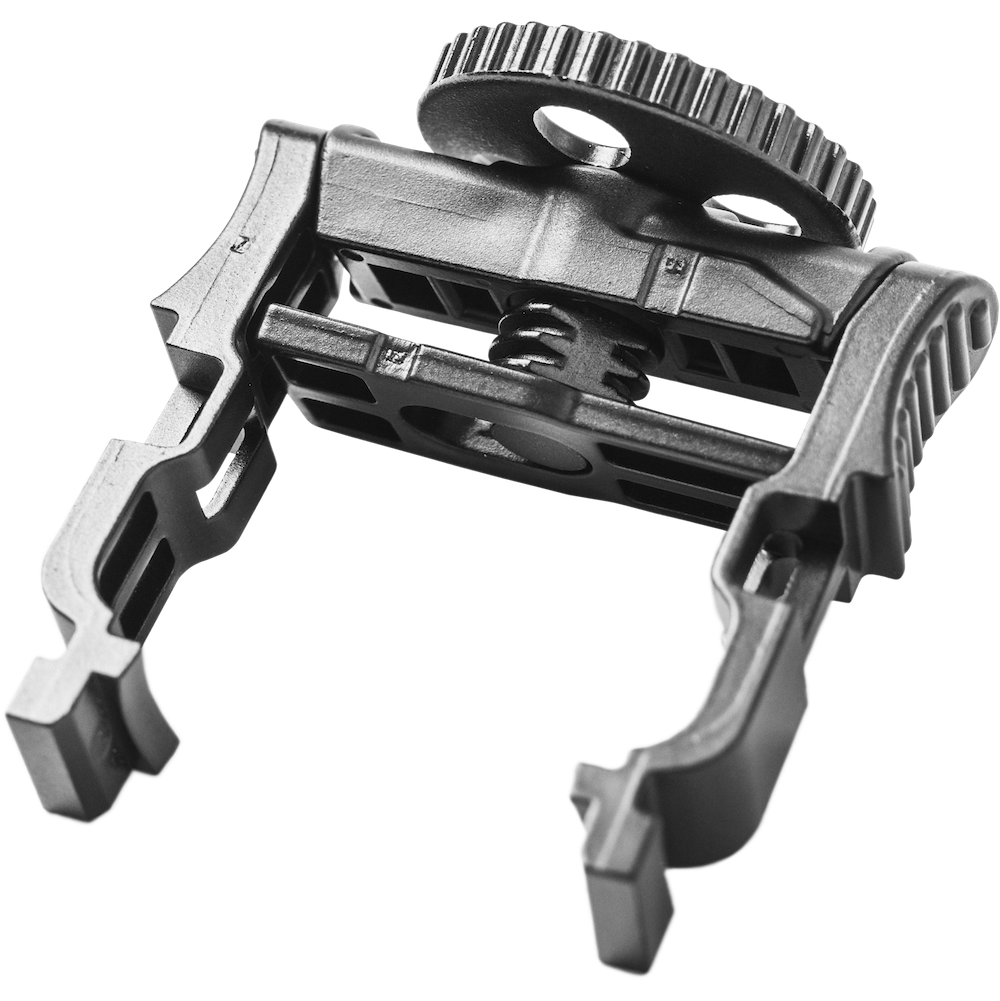

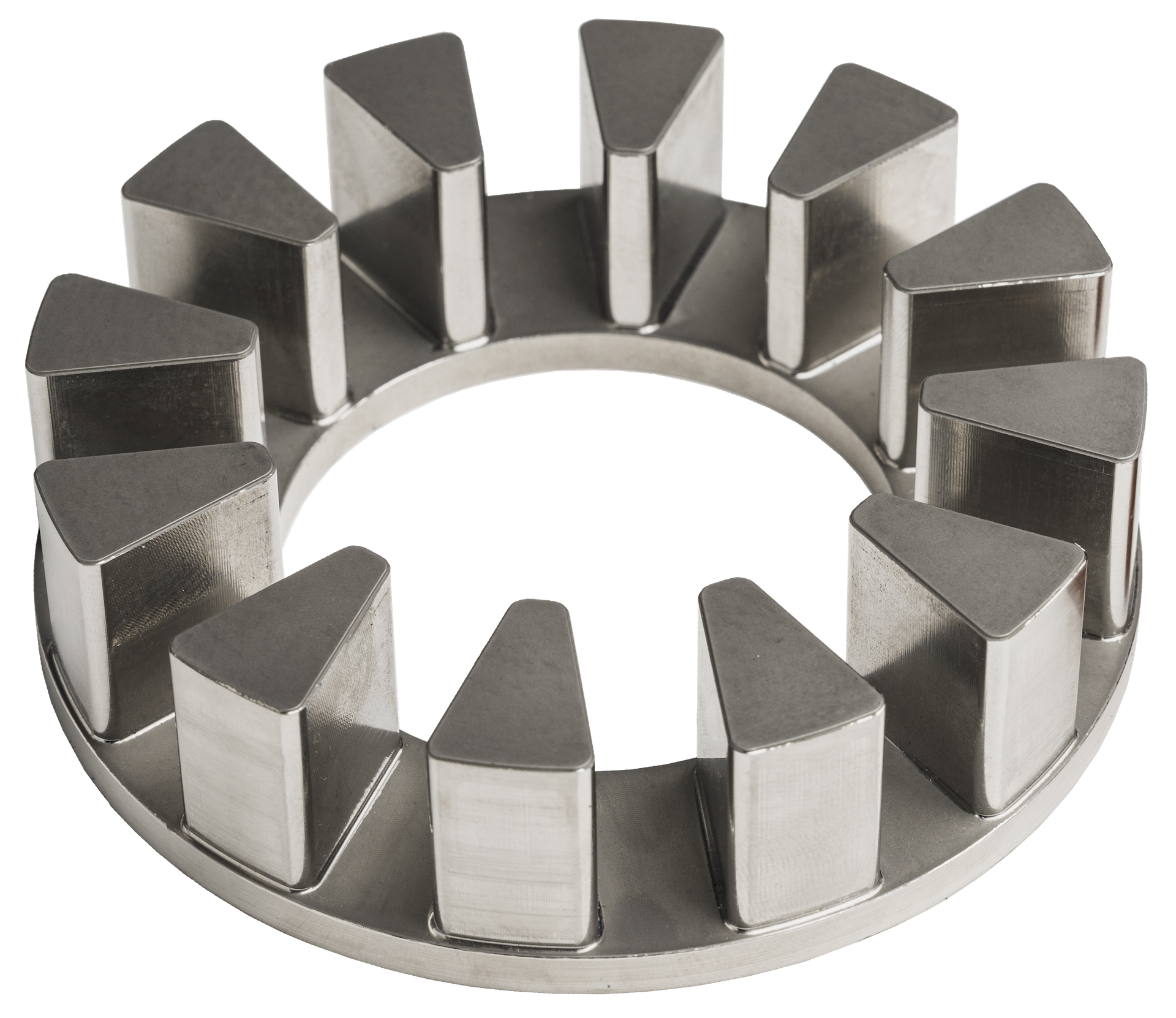

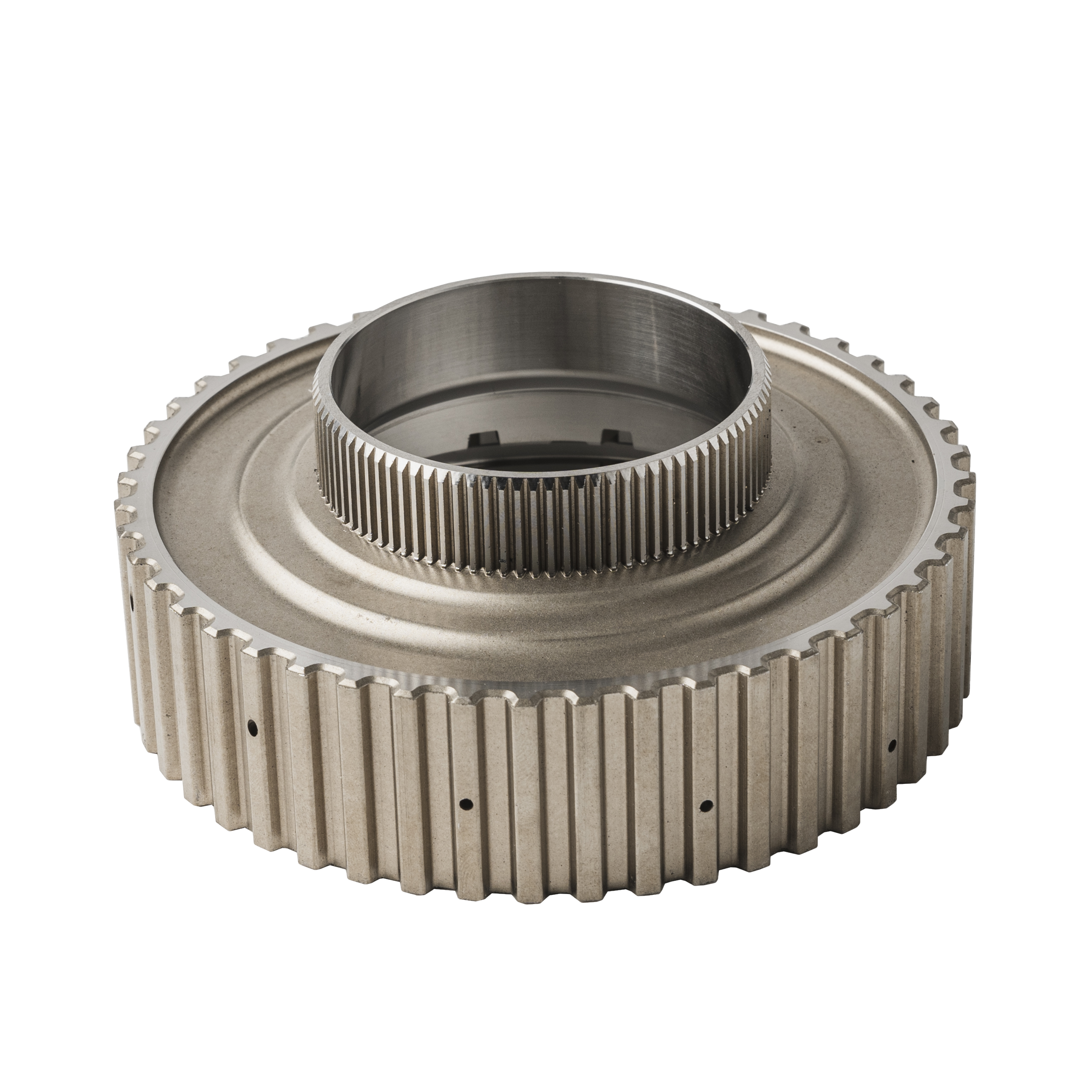

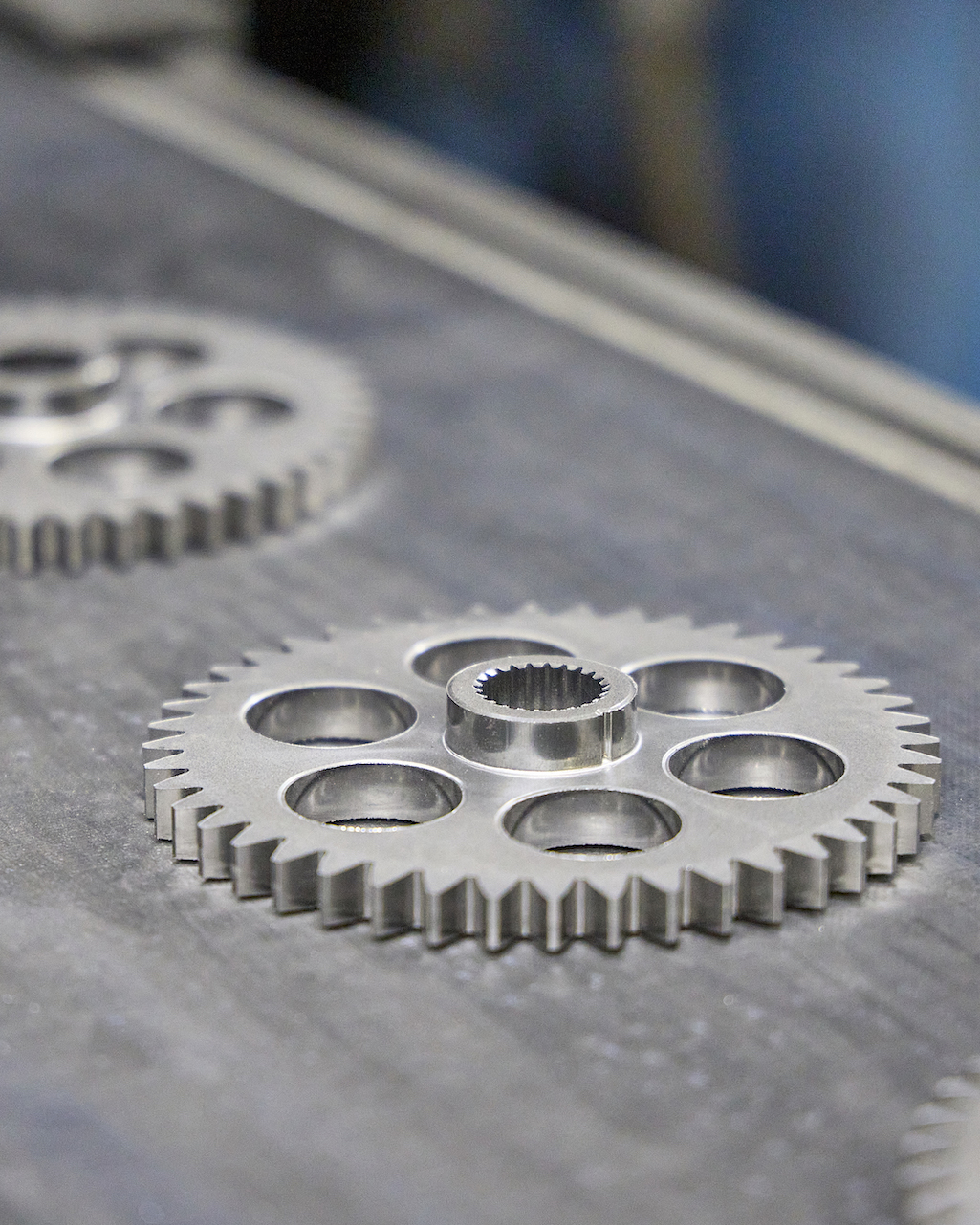

Struggling to meet the demands for high precision and functionality in your products? Our engineering team excels in transforming complex requirements into effective metal solutions using innovative technologies and custom powder manufacturing. From the initial concept to the final product, we leverage techniques like metal injection molding and powder metallurgy, ensuring every component is not only tailored to fit but optimized for performance.

You envision the future, and MPP engineers bring it to life. With 75 years of pioneering or advancing powder metal technology and developing innovative metal products, we are dedicated to delivering electrification solutions and custom-engineered components that evolve with your needs.

Technology Tailored to Your Success

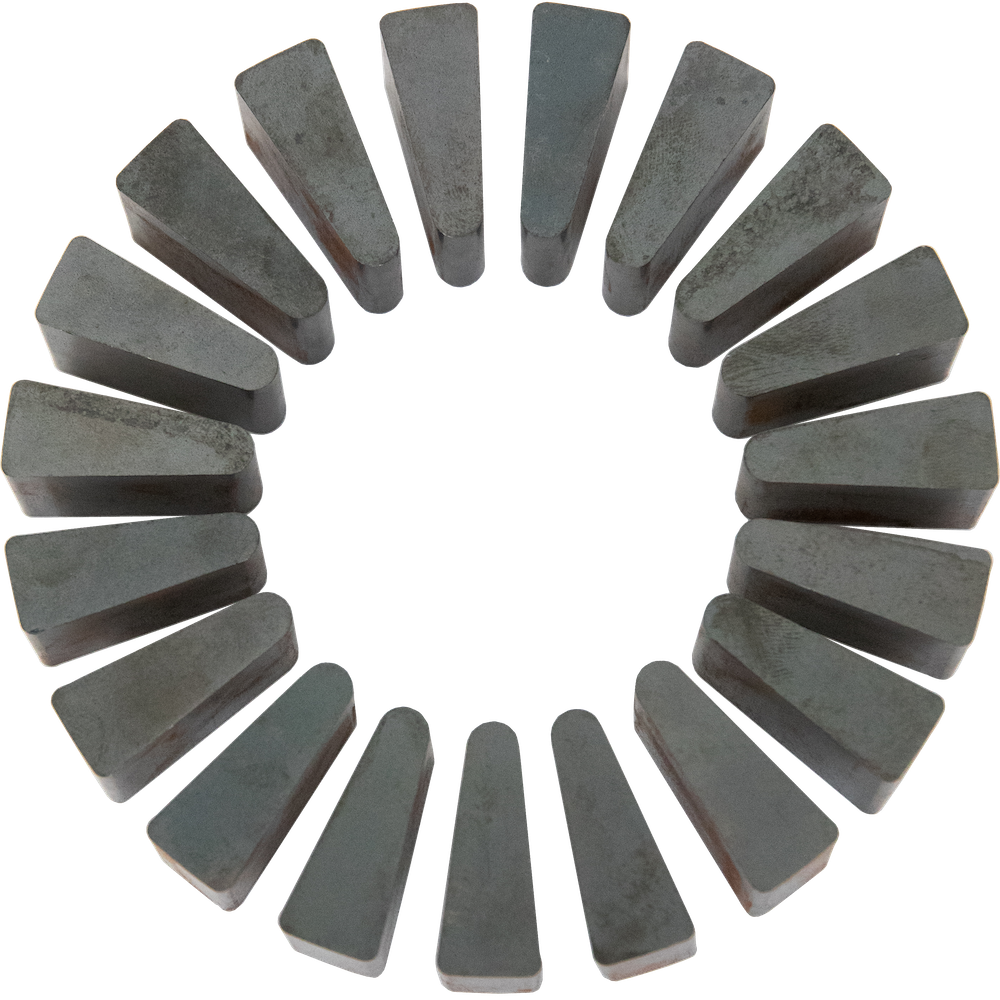

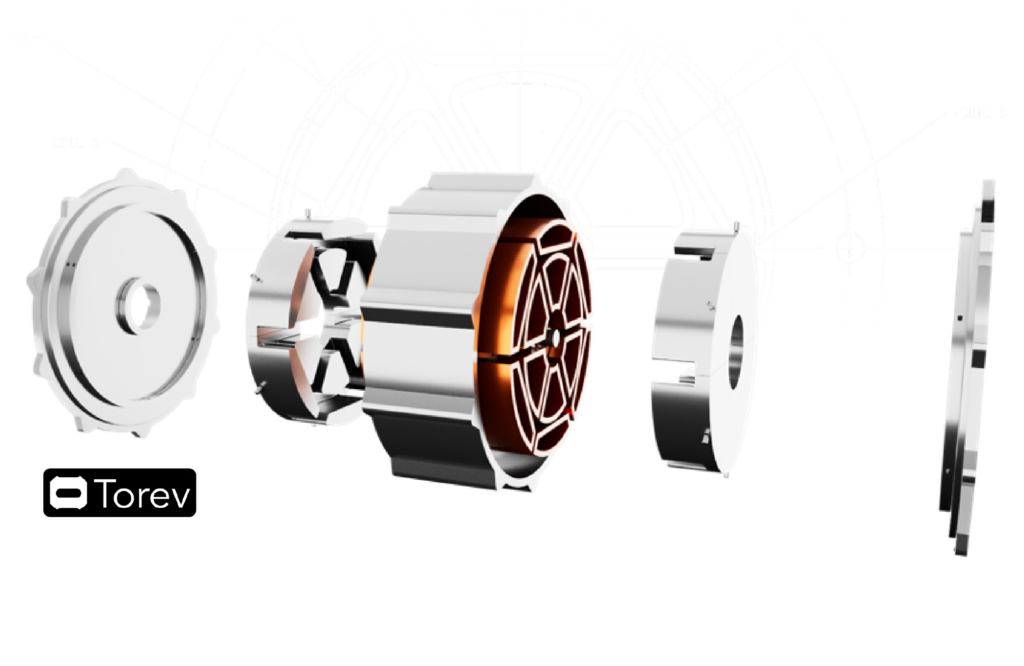

Electrifying

Your Products with

Soft Magnetic Composites

Experience the transformative benefits of Soft Magnetic Composites (SMC) with MPP. Our SMC technology empowers your products by reducing the need for rare earth magnets, enabling compact, lightweight, and energy-efficient designs that enhance your competitive edge.

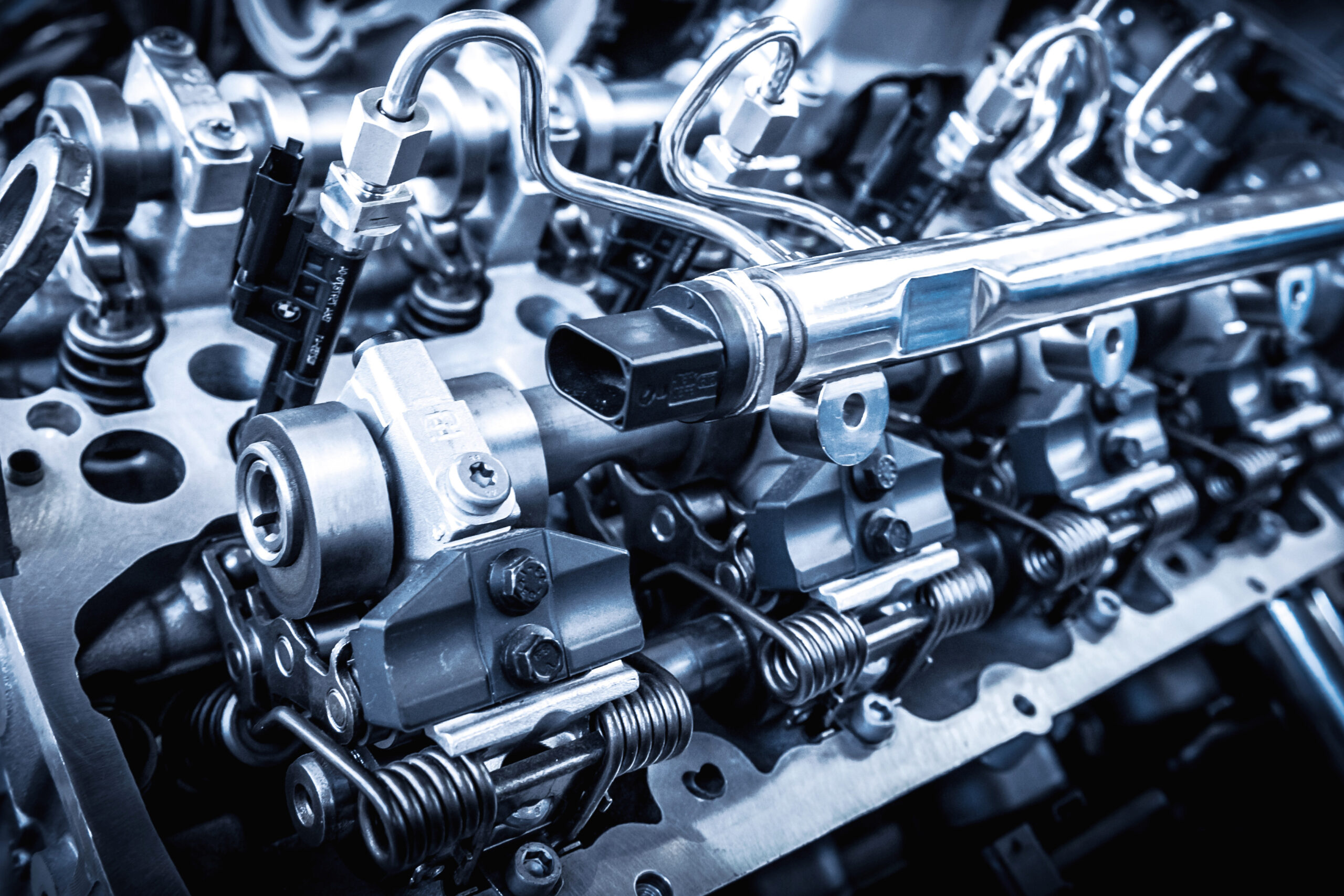

Markets We Empower

MPP is dedicated to enhancing your products across a variety of markets: