Driving

Efficiency

in

Off-Highway and Agriculture

Strength, Precision, Performance

The off-highway and agriculture market faces many challenges, from demands for increased efficiency to stringent environmental regulations, that make a shift towards advanced materials and manufacturing techniques necessary. By leveraging PM technology, your components can excel in durability, precision, and performance in heavy truck and off-highway applications.

- High strength and durability: PM components can withstand rigorous demands for operations including high loads, vibrations, wear resistance, and extreme temperatures.

- Design freedom: Intricate and complex geometries can be achieved without compromising structural integrity and are tailored for specific performance requirements.

- Cost-effective: PM offers cost-effective solutions by minimizing material waste and reducing machining requirements.

Customized Solutions for Heavy Equipment

Collaborate with engineers that specialize in powdered metal solutions, working closely with you to design components that meet your unique specifications and ensure optimal performance within your off-highway and agriculture systems.

New Design & Conversioneering

Whether you’re interested in designing a new part, converting your components to powder metal, or looking to improve the performance of your current designs you’ll go through a hands on process – from initial conception to completed design. By involving the MPP team as an extension of your engineering department early in the development process, you’re guaranteed maximum value and robust solutions.

Want to learn more about how powder metallurgy works?

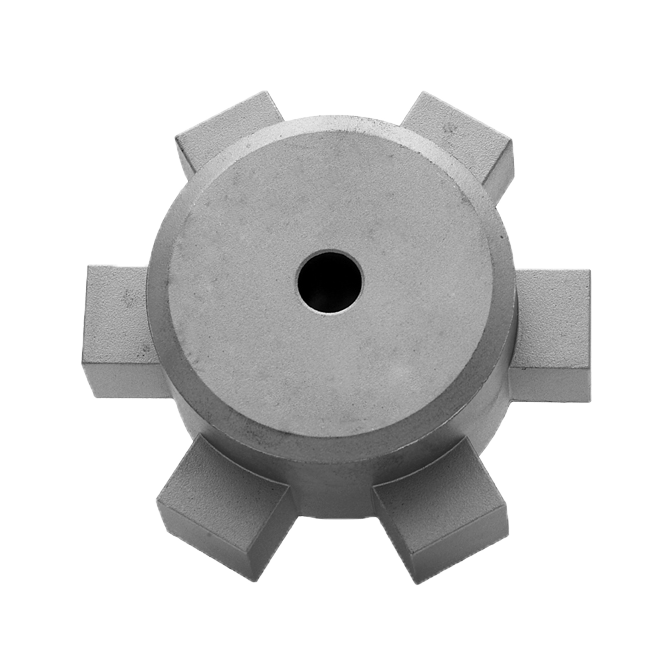

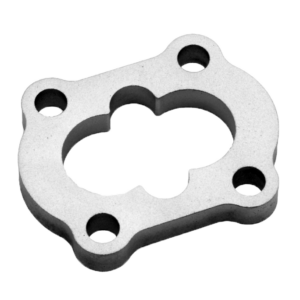

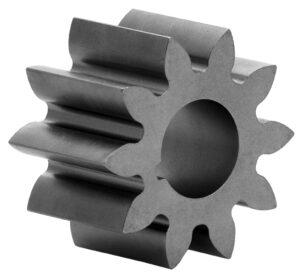

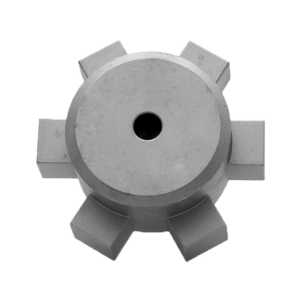

Parts We Specialize In

PM Technology in Off-Highway Applications

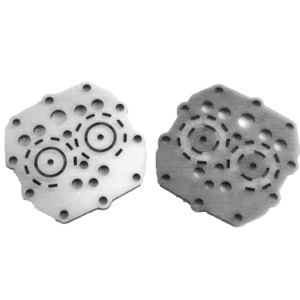

Utilizing powder metallurgy, you can substantially slash costs and streamline your manufacturing processes for heavy equipment compared to traditional machining methods. For parts that need to be pressure sealed such as pump covers, end caps, spacers, etc, PM, through resin impregnation and/or steam treatments, seals those parts to prevent any leaking throughout the system.

Work with a team that has experience in the development of powdered metal components for off-highway and agriculture markets including construction, mining, and agriculture equipment.

- Transmission clutch rings, large mechanical components

- Large precision finished spur gears and ring gears for engine, transmission, and final drive components

- High-pressure sealed components for fluid, vacuum, and air

- Finished oil and fuel transfer pump components, including gerotors

- Steering vane pump and braking components

- ABS components

- Differential components

Powder Metal in Action

Want to see if PM is the right fit for you?

Request a Tech Day where our experts will walk you through the PM process, our capabilities, and learn more about your project.