The Power of PM in Cost Efficiency

A heavy equipment manufacturer

A senior design engineer at the heavy equipment manufacturer sought collaboration with MPP to explore cost-saving opportunities within their assembly lines. The customer identified a labor-intensive process that involved purchasing four separate components and employing a welder to fuse them together. This method proved to be both expensive and slow.

A heavy equipment manufacturer

A senior design engineer at the heavy equipment manufacturer sought collaboration with MPP to explore cost-saving opportunities within their assembly lines. The customer identified a labor-intensive process that involved purchasing four separate components and employing a welder to fuse them together. This method proved to be both expensive and slow.

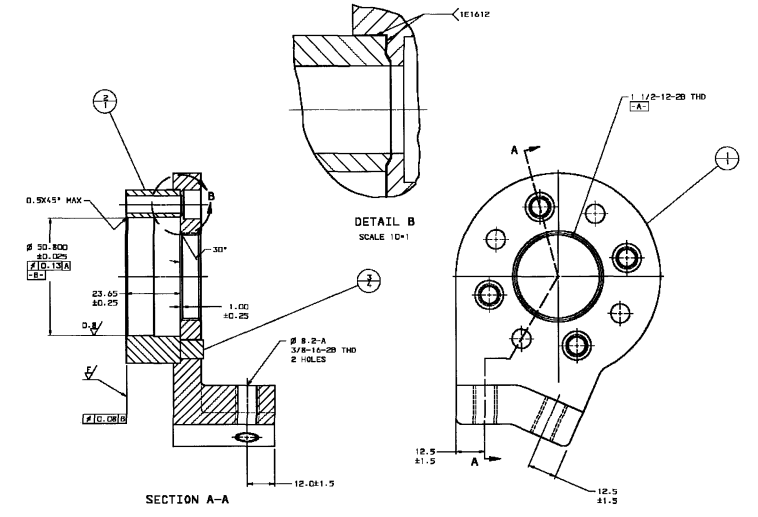

In close collaboration with the customer's design engineers, MPP developed an innovative solution—a two-piece sinter-brazed design using PM technology. This new approach replaced the current four-piece weldment process. During the collaborative process, engineers identified the potential to use two different powders strategically, optimizing cost-effectiveness by employing the higher-priced material only where wear properties were essential for the application. By supplying a single part solution to the customer, they were able to not only save money with the PM option, they were able to eliminate a much slower welding process and reduce the number of components from four to one, consequently reducing inventory.

The transformation from a four-piece weldment to a two-piece sinter brazed part, coupled with the strategic use of premium powder, resulted in a 72% overall cost savings compared to the previous process. Beyond the financial benefits, this solution enhanced efficiency, simplified manufacturing, and contributed to a more streamlined inventory.

The transformation from a four-piece weldment to a two-piece sinter brazed part, coupled with the strategic use of premium powder, resulted in a 72% overall cost savings compared to the previous process. Beyond the financial benefits, this solution enhanced efficiency, simplified manufacturing, and contributed to a more streamlined inventory.