Electrifying

the Market with

Soft Magnetic Composites

Keep up with Growing Demand

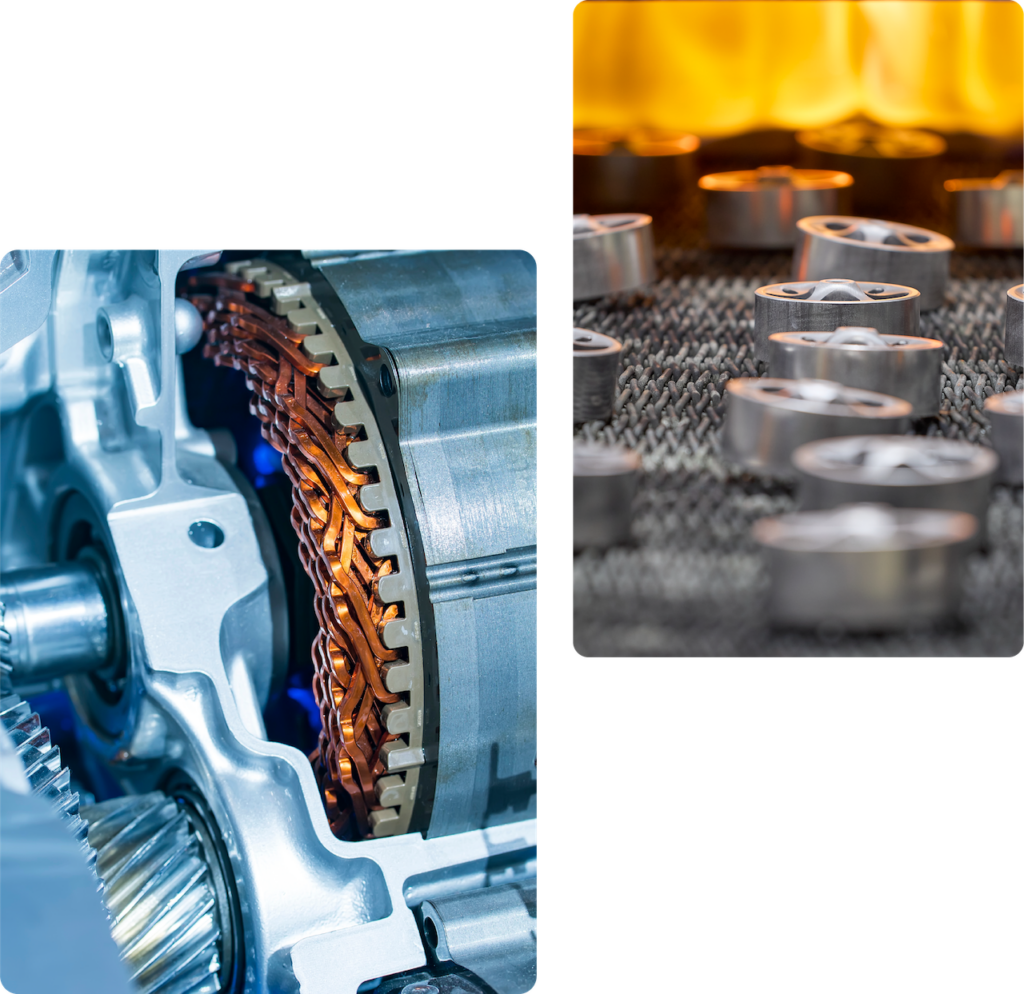

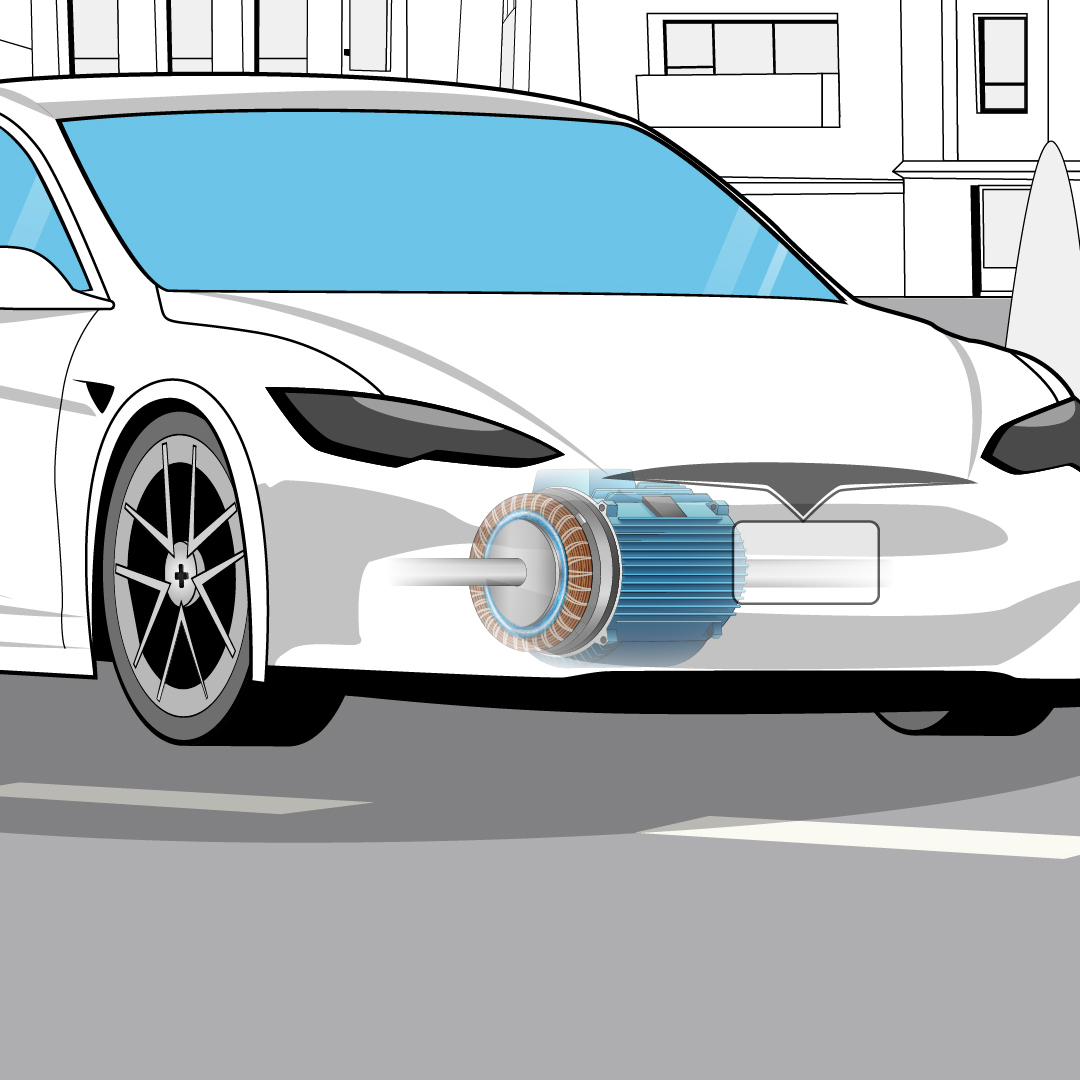

Soft magnetic composites (SMCs) are playing a crucial role in the shift to electrification. Each powder particle is coated with an insulation layer, thus allowing the PM process to press the parts to the net shape in a single pressing, creating the lamination stack for a brushless direct current motor (BLDC) application. With SMCs, you’ll be able to keep up with the growing demand for electric motors and continue to innovate as technology moves ahead in the future.

Advantages of Soft Magnetic Composites

As the market’s leading producer of SMC parts, we use our knowledge and expertise to maximize the advantages of SMCs.

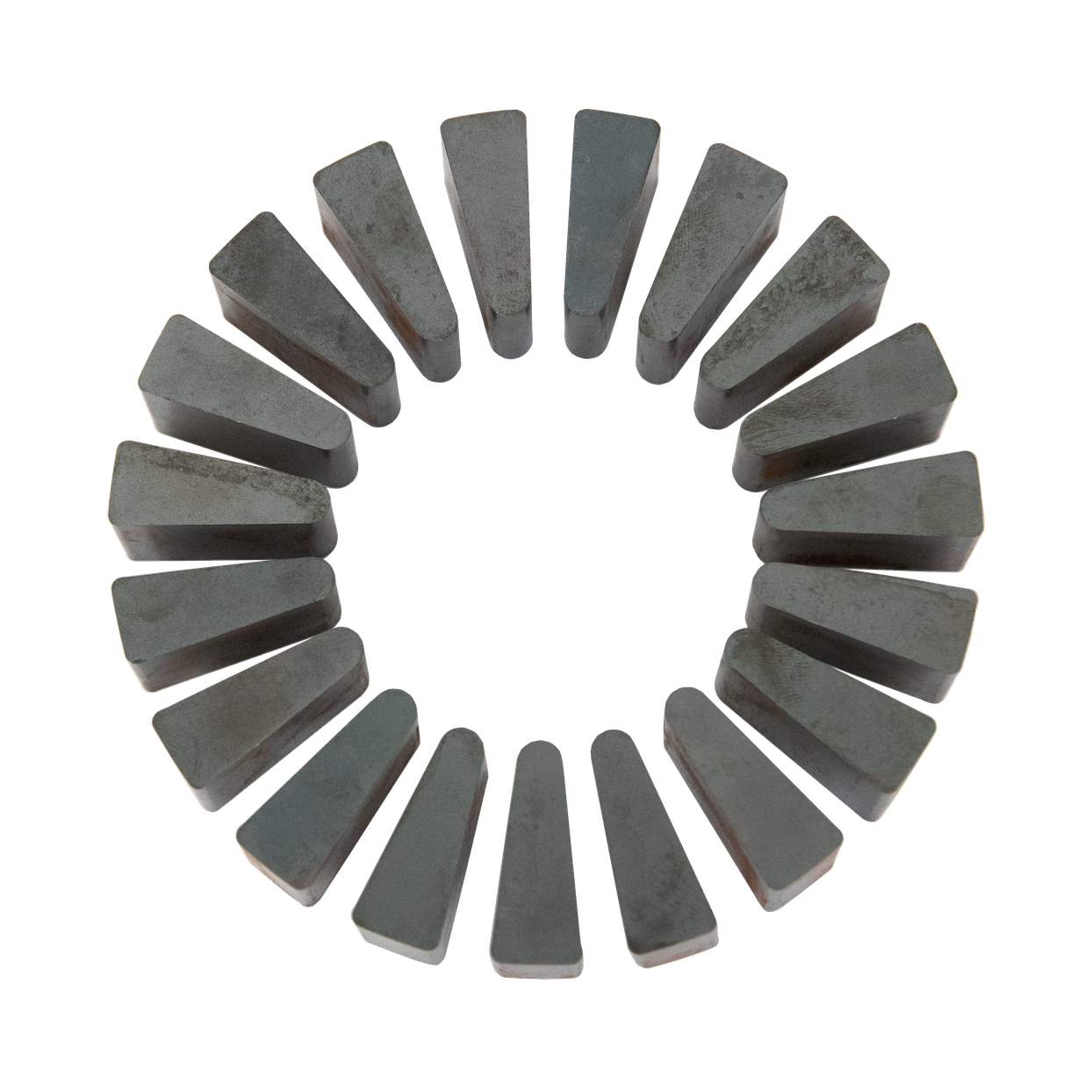

- Design freedom: SMC materials can be molded into any shape, allowing for design freedom in a variety of applications.

- Reduced energy loss: The insulation layers in SMC materials lower eddy currents, reducing frequency-dependent losses and improving energy efficiency.

- Compact and powerful motors: SMC materials make it possible to design innovative, compact, and powerful electric motors that match specific applications. The 3D flux path allows for more powerful and efficient motor design. Additionally, using SMCs means you can design motors that use no earth magnets, reducing overall cost while increasing motor efficiency.

Sintered Soft Magnetics

Sintered Soft Magnetics (SSM) are advanced magnetic materials produced through powder metallurgy, offering customizable magnetic properties, high performance, structural strength, and cost-effective manufacturing. Their versatility and diverse applications make them valuable for various industries, contributing to efficient and reliable DC magnetic devices. With a broad range of materials like iron, silicon, and nickel alloys, SSM materials boast varying magnetic properties and structural strength. Permeability, saturation, and coercivity dictate critical magnetic performance. Advanced compaction technologies and elevated sintering temperatures enable higher perm and saturation, even reaching permeabilities of 7000. SSM materials find applications in flux return paths, solenoids, relays, motors, and more.

Soft magnetic composites are a versatile tool for a variety of applications. Some of the most notable applications of SMCs include:

Learn about our solutions across multiple industries.

Resources

Soft Magnetic Composites Overview