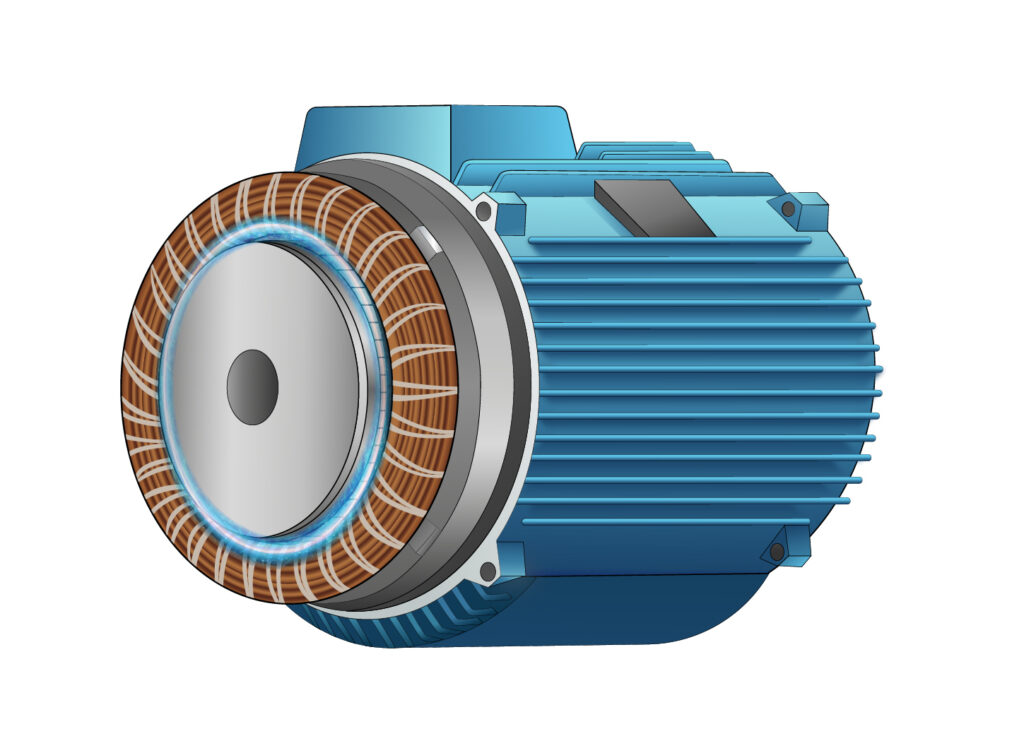

Axial Flux with No Rare Earth Magnets

A leading electric motor manufacturer

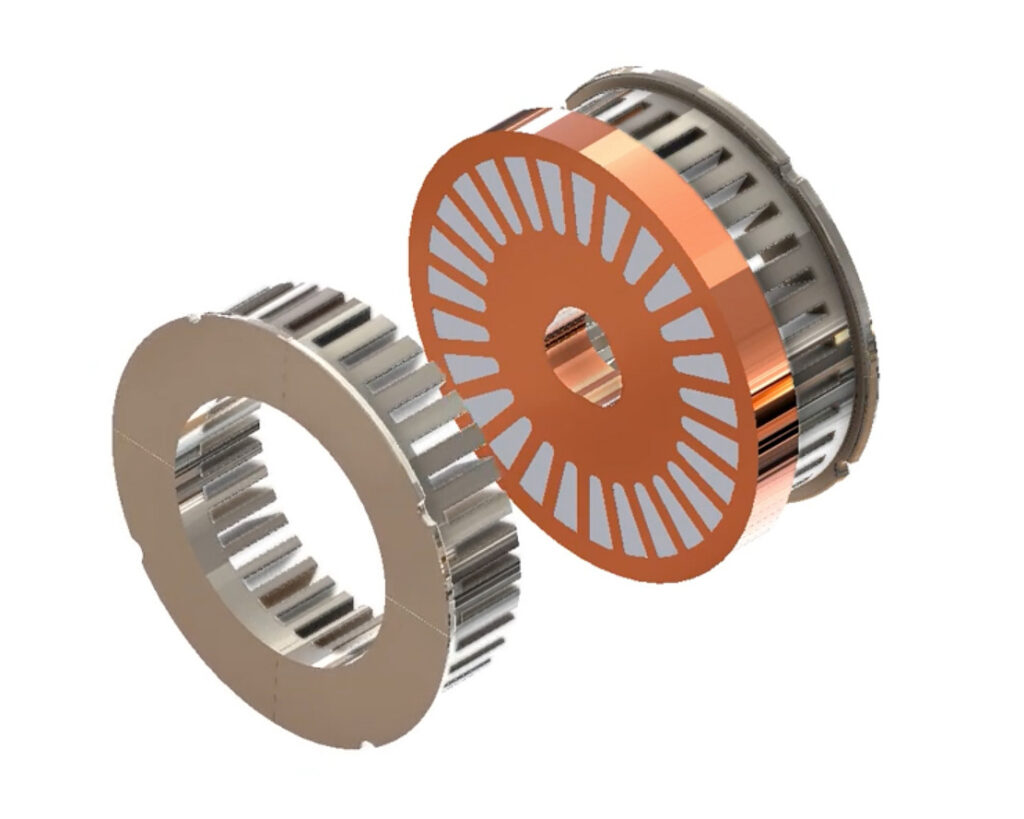

A chief engineer from a new technology company came to MPP on a quest for innovation. They urgently sought an alternative joining process for SMC inserts and copper to manufacture an induction rotor assembly destined for an axial flux motor. The existing joining process had its drawbacks, involving numerous post-processing steps and substantial material removal to achieve flatness and rotor balance.

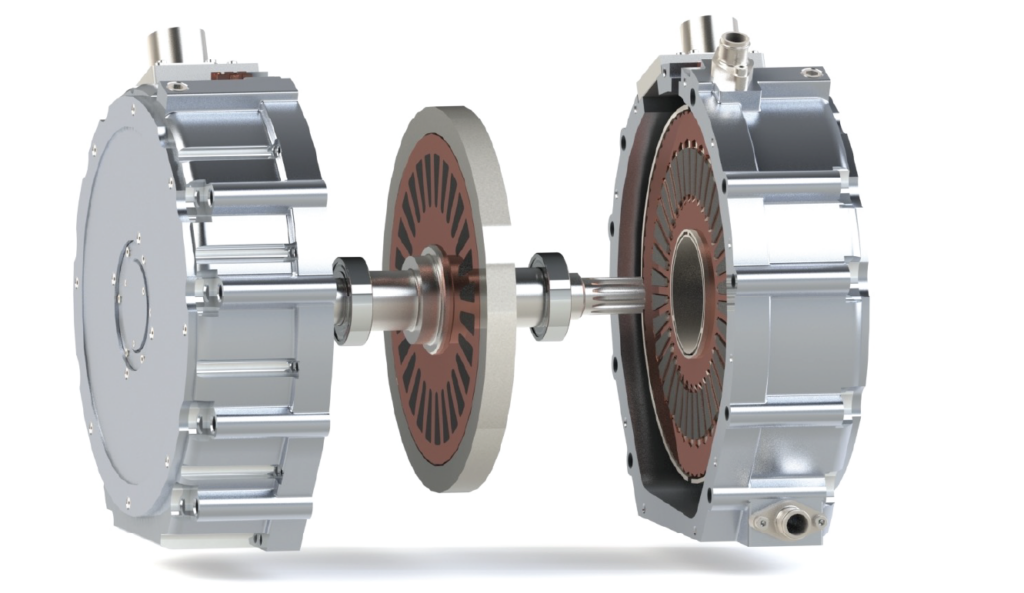

The new process they envisioned had lofty ambitions. It aimed to not only bolster production capacity but also deliver a statistically capable process that would eliminate waste. Crucially, it had to produce a ready-to-assemble rotor, meeting criteria for overall length, flatness, and balance to support the airgap tolerance requirements of a dual stator motor configuration.

A leading electric motor manufacturer

A chief engineer from a new technology company came to MPP on a quest for innovation. They urgently sought an alternative joining process for SMC inserts and copper to manufacture an induction rotor assembly destined for an axial flux motor. The existing joining process had its drawbacks, involving numerous post-processing steps and substantial material removal to achieve flatness and rotor balance.

The new process they envisioned had lofty ambitions. It aimed to not only bolster production capacity but also deliver a statistically capable process that would eliminate waste. Crucially, it had to produce a ready-to-assemble rotor, meeting criteria for overall length, flatness, and balance to support the airgap tolerance requirements of a dual stator motor configuration.

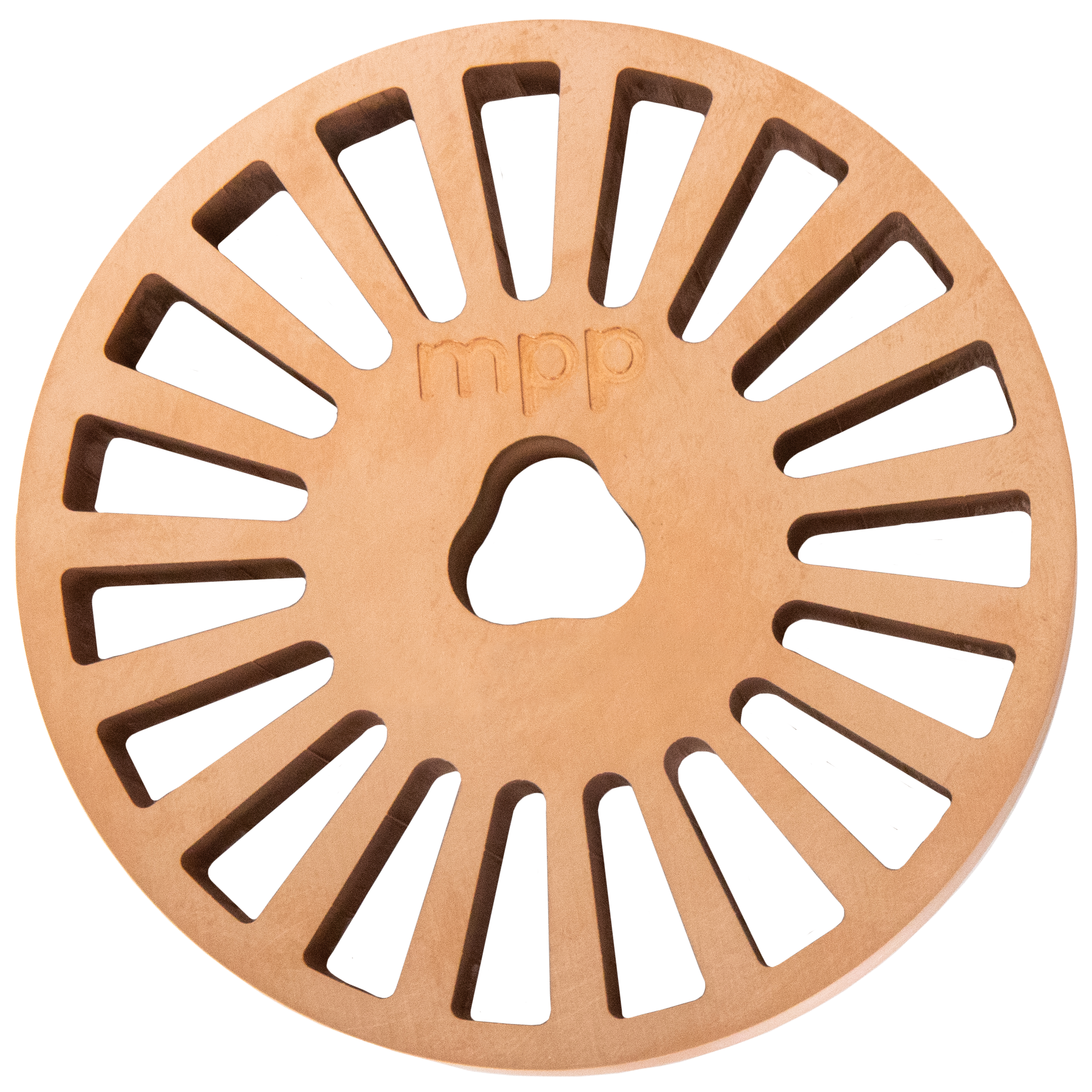

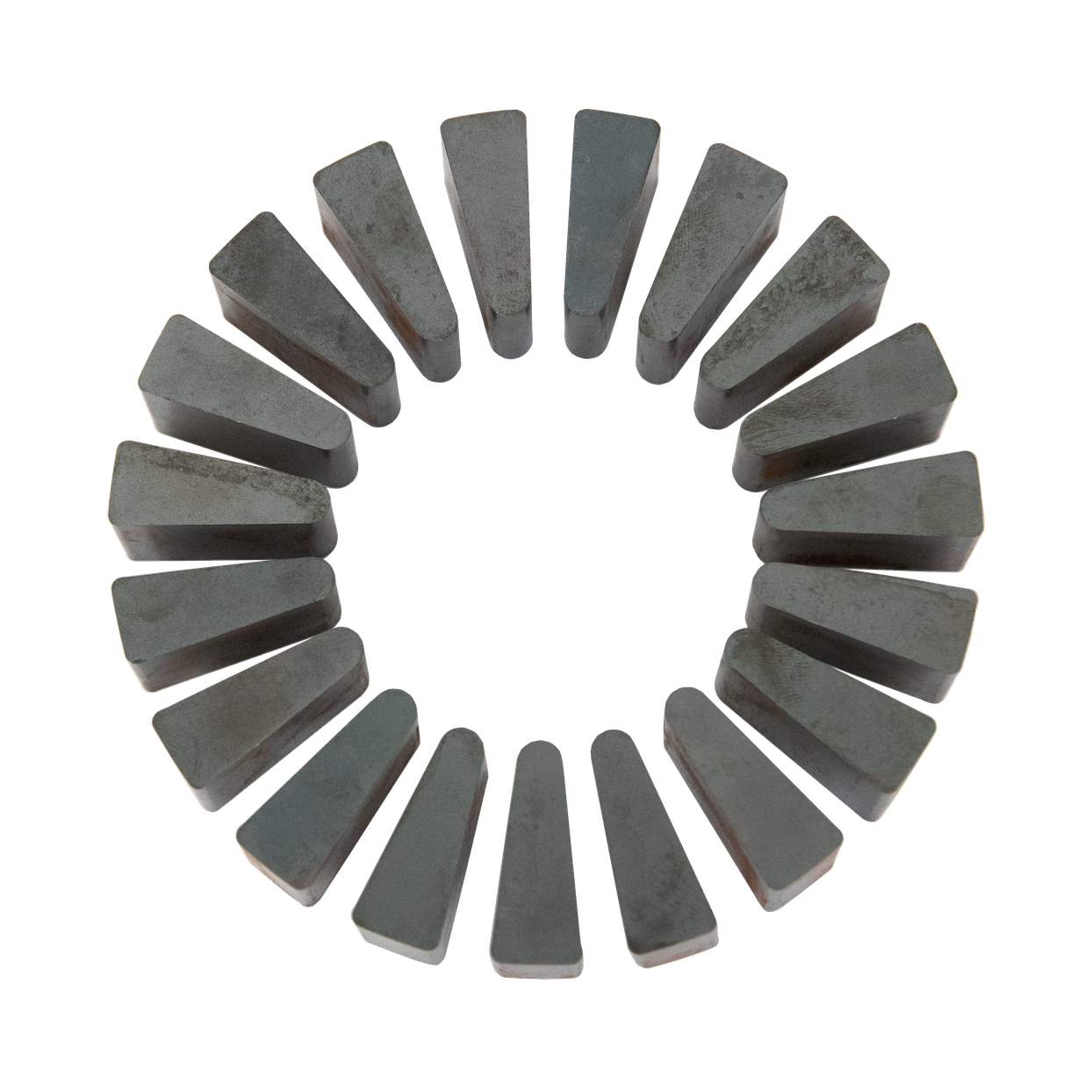

Through close collaboration, MPP utilized Design of Experiment tools to generate data and explore materials that could enhance the original component’s performance. After demonstrating the feasibility of the materials and processes, MPP developed Finite Element Analysis models. Using these models, we further refined the component’s design to align with the customer’s exacting standards for thermal, mechanical, and electrical conductivity.

Upon receiving approval of the design, we utilized our unique powder metal processes to manufacture hybrid copper and SMC components, culminating in the fabrication of a ready-to-assemble rotor. Rigorous evaluation followed, with the customer subjecting the assemblies to dyno tests and real-world applications.

The new rotor design and manufacturing process yielded astounding results. The company benefited from a 50% reduction in costs. Moreover, they are now ready to support high-volume production. This project stands as a testament to the power of collaboration and innovation, propelling the electric motor industry forward into a new era of efficiency and excellence.