Leading the Future with Advanced Powder Metal Technology

Material Development

Our expertise in advanced material development allows us to craft custom powder blends using a wide range of metals, including aluminum, iron, steel, brass, bronze, copper, and soft magnetic composites. By collaborating closely with design engineers, we formulate ideal metal powder compositions tailored to your application needs. We focus on desired characteristics, performance requirements, and environmental considerations. Through rigorous testing and refinement, our metal powder products consistently surpass the highest quality, reliability, and functionality standards. Whether you need enhanced strength, improved corrosion resistance, or specific mechanical properties, our powder metallurgy solutions deliver exceptional results.

Material Development

With our expertise in material development, we specialize in crafting custom powder blends and working with a wide range of metals, including Aluminum, Iron, Steel, Brass, Bronze, Copper, and Soft Magnetics. Collaborating closely with design engineers, we formulate the ideal metal powder composition by identifying desired characteristics, performance requirements, and environmental considerations. Rigorous testing, analysis, and refinement ensure that the resulting material surpasses the highest quality, reliability, and functionality standards. Whether enhancing strength, improving corrosion resistance, or achieving specific mechanical properties, we always deliver exceptional results.

Powder Metallurgy

Utilizing cutting-edge powder metallurgy, we combine the optimal mix of metal powders to meet your unique strength and performance requirements. Our advanced powder products are designed to create customized, complex, sustainable components that enhance your application.

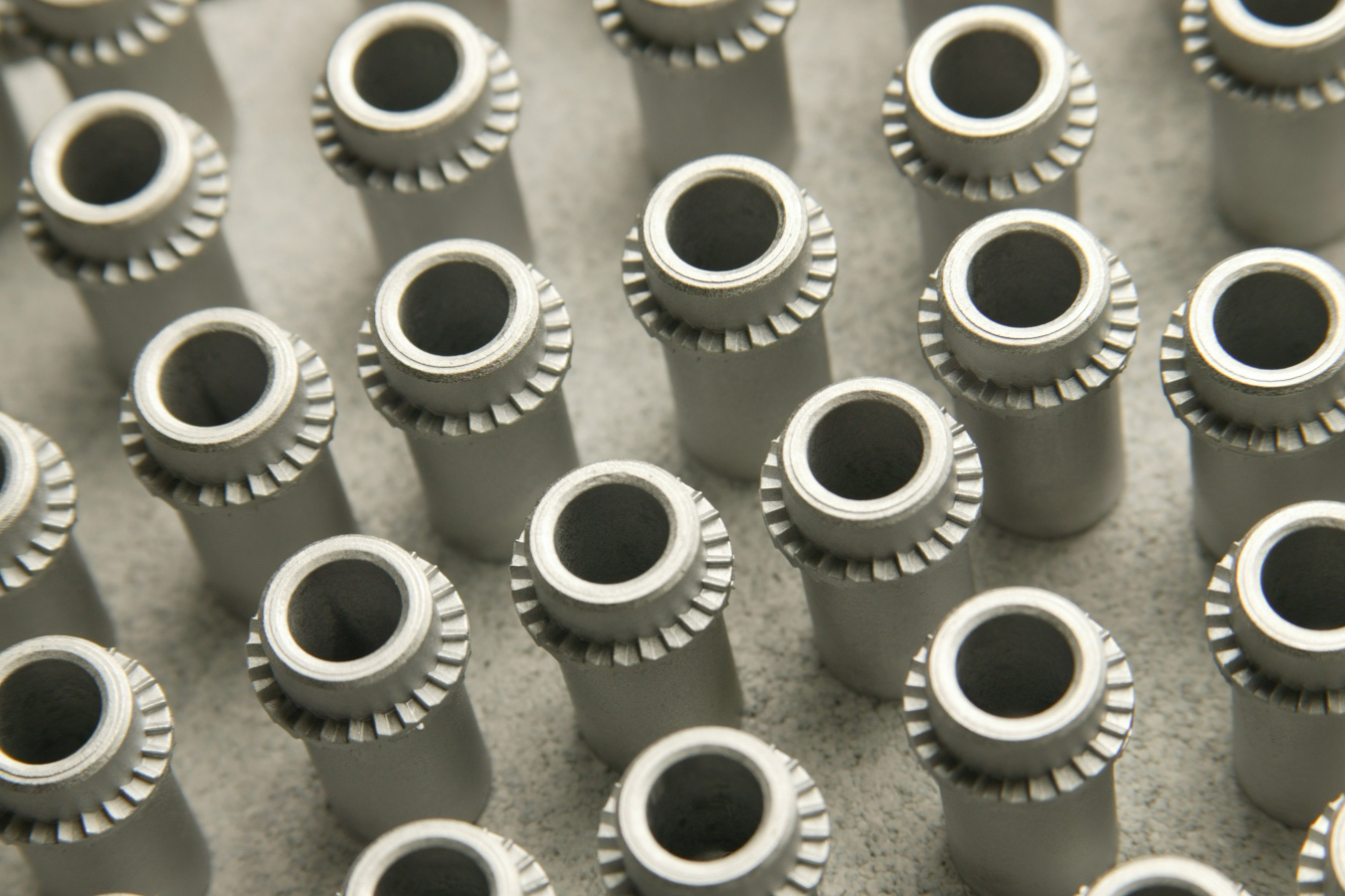

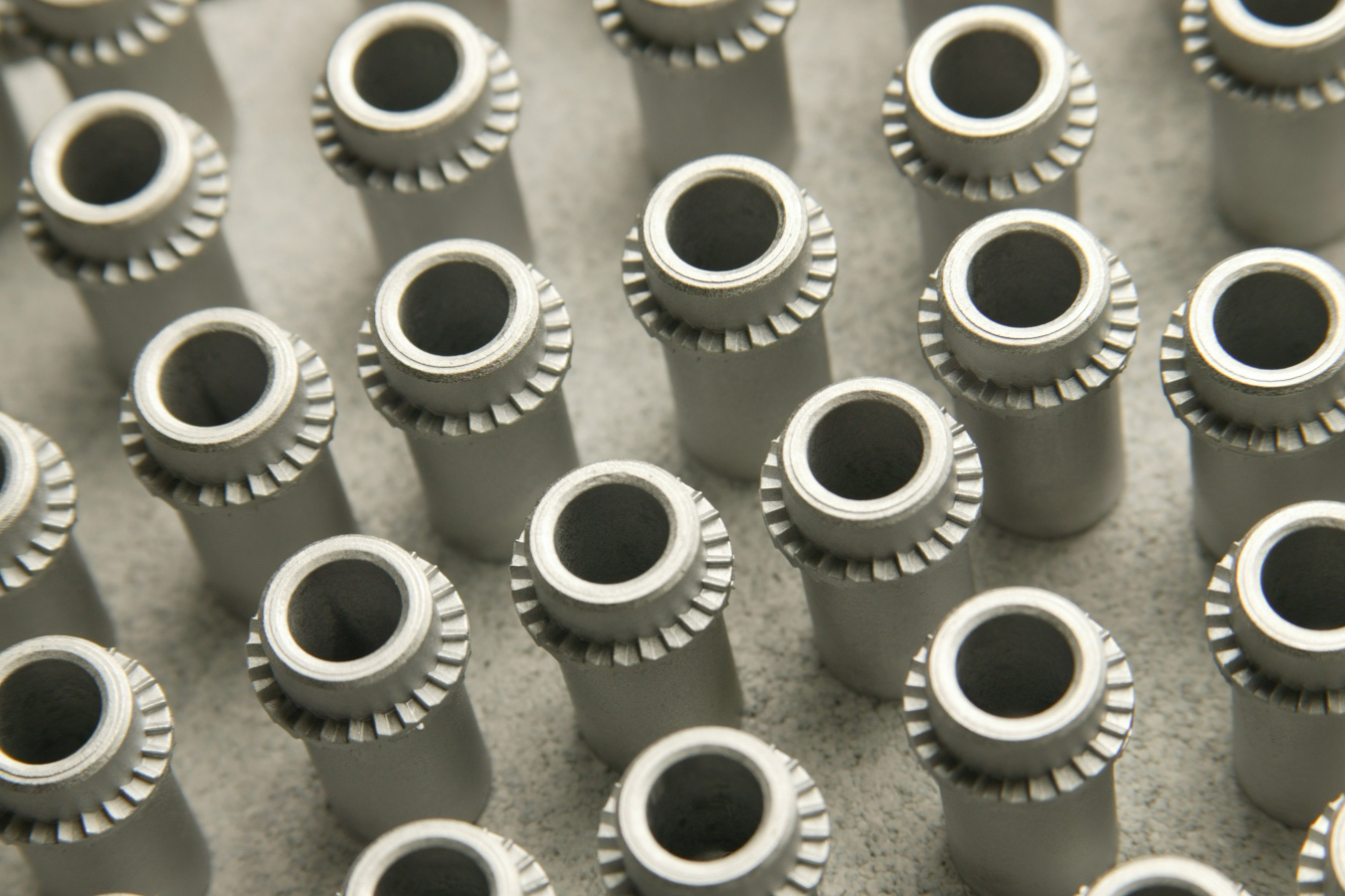

Metal Injection Molding

Our metal injection molding (MIM) process offers a cost-effective solution for producing complex, high-volume components. This advanced powder metal technology can replace traditional metal forming techniques, such as investment casting and machining, with the potential to integrate multiple piece assemblies into one seamless component.

Metal Injection Molding

As a cost-effective solution ideal for simplifying the production of your complex, high-volume components, the MIM process can replace other metal forming techniques such as investment casting and machining and has the potential to incorporate multiple piece assemblies into one component.

Soft Magnetics

Soft magnetic composites represent a breakthrough in the future of electrified applications. This innovative technology, coupled with net-shape forming capabilities, offers significant advantages over traditional lamination stack production, enhancing efficiency and performance.

(SMCs) are isotropic, high-resistive materials that enable compact motor designs with 3D flux and low eddy currents. SMC stator cores provide unique design options that are not achievable with stacked laminations.

Aluminum

Aluminum powder metallurgy provides lightweighting advantages, and improved thermal conductivity for high-performance applications. Our aluminum technology innovations allow us to optimize shape and performance for your specific applications, ensuring superior results.

Aluminum

Aluminum’s light weight and strength provide an excellent strength-to-weight ratio. Aluminum offers product forms and alloys that surpass any other material. Its design flexibility allows us to optimize shape and performance needed for your specific application.