Machined to MIM Conversion

A leading company that creates Orthopedic Surgical Devices

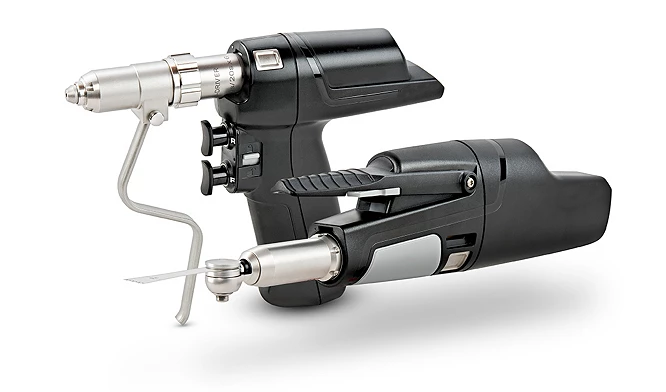

An engineer from a prominent company specializing in orthopedic surgical devices turned to MPP with an urgent challenge. They needed a fresh approach to manufacture a part that had traditionally undergone extensive machining. This machining process not only generated massive waste but also prolonged the lead time to produce the final product. With surging demand for this vital component, the company faced a pressing need to accelerate production, reduce costs, and minimize waste. In their quest for a solution, they approached MPP with a finished part, seeking innovation through the Metal Injection Molding (MIM) process.

A leading company that creates Orthopedic Surgical Devices

An engineer from a prominent company specializing in orthopedic surgical devices turned to MPP with an urgent challenge. They needed a fresh approach to manufacture a part that had traditionally undergone extensive machining. This machining process not only generated massive waste but also prolonged the lead time to produce the final product. With surging demand for this vital component, the company faced a pressing need to accelerate production, reduce costs, and minimize waste. In their quest for a solution, they approached MPP with a finished part, seeking innovation through the Metal Injection Molding (MIM) process.

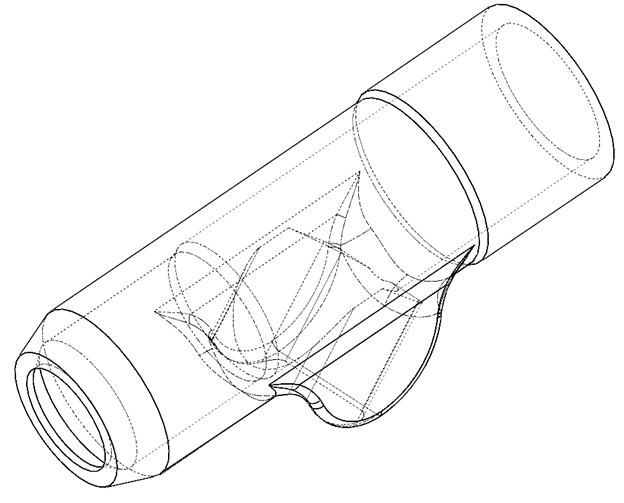

This company opted to collaborate with MPP due to our expertise in producing MIM components at a substantial scale. While this particular program represented a lower volume than what many MIM providers typically handle, MPP recognized the intricacy of the part and the importance of supporting a customer creating such important devices. We meticulously examined the finished part and its accompanying drawings, leading us to the development of an improved MIM blank within the tolerances needed for their small surgical device. This breakthrough significantly slashed machining time and delivered substantial cost savings.

The MIM-produced blank translated into a staggering 75% reduction in machining time. This pivotal transformation enabled the customer to ramp up production of this crucial component, ensuring a more abundant supply to their end customers. This leap in efficiency was implemented without compromise to the quality or functionality of the part. In essence, by embracing MIM, the company achieved a triumphant blend of superior performance, cost-effectiveness, and accelerated production.