Plastic to MIM Conversion

A leading company who works in underwater robotics

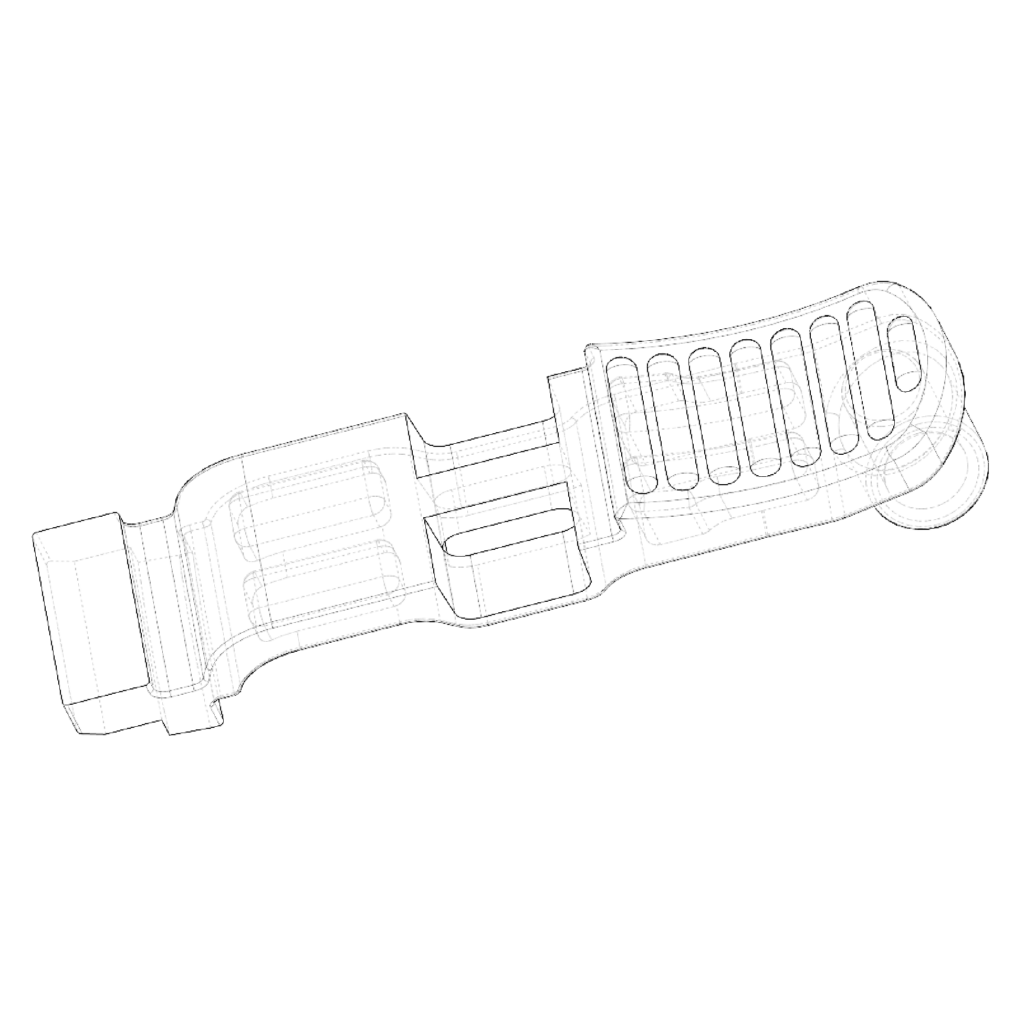

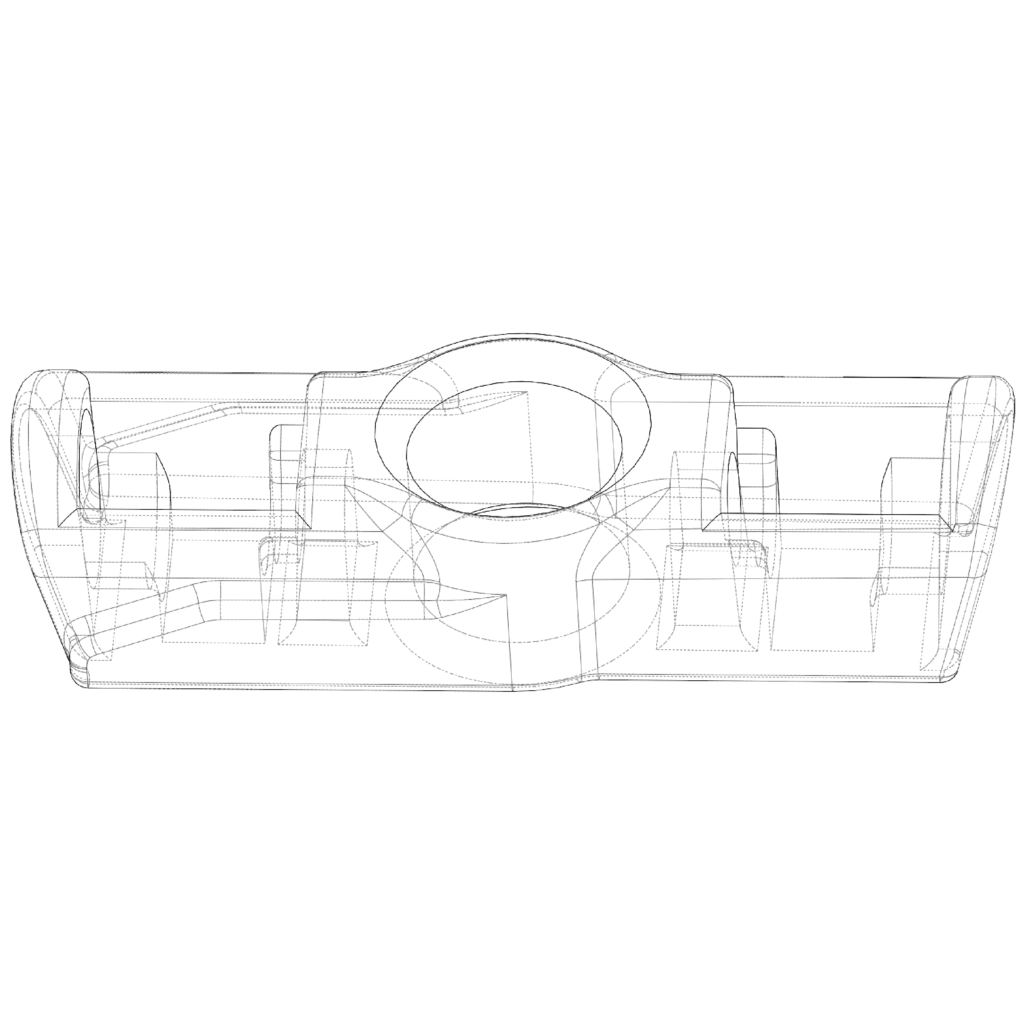

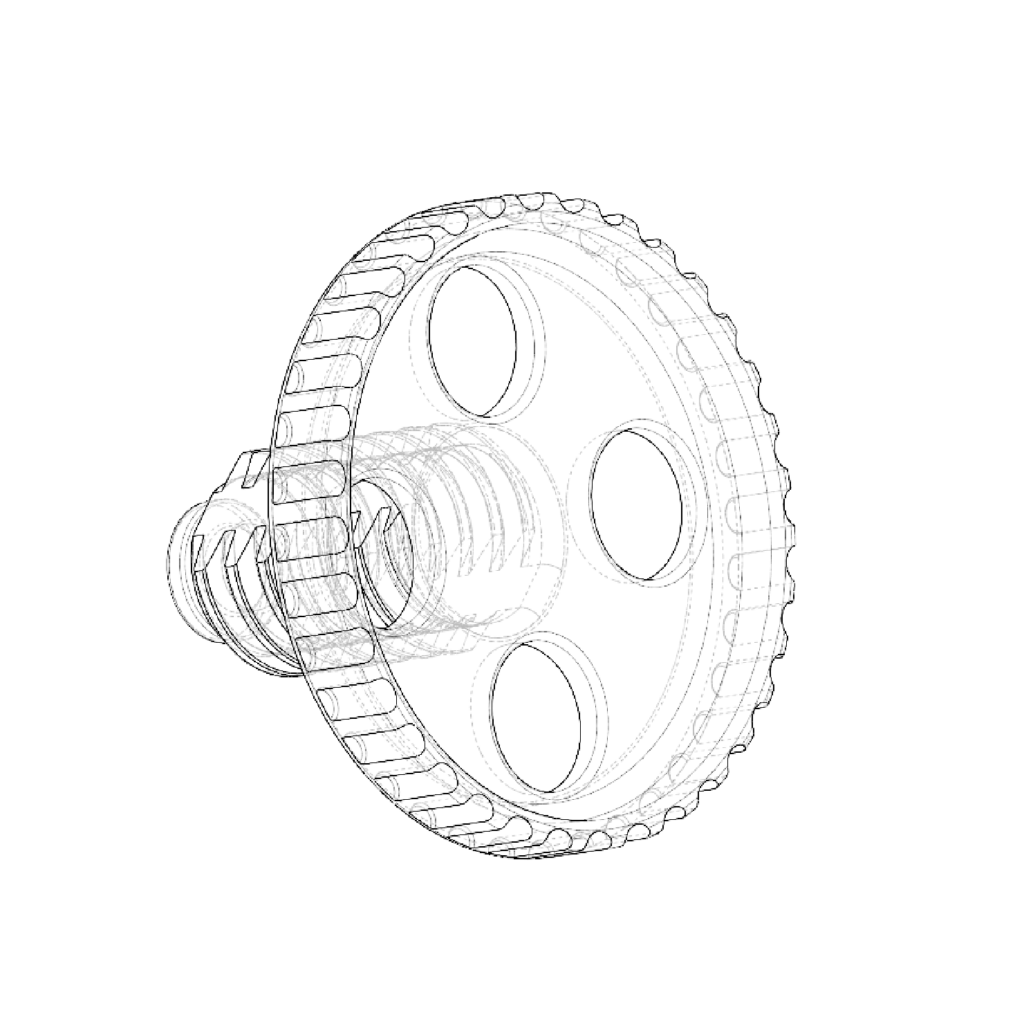

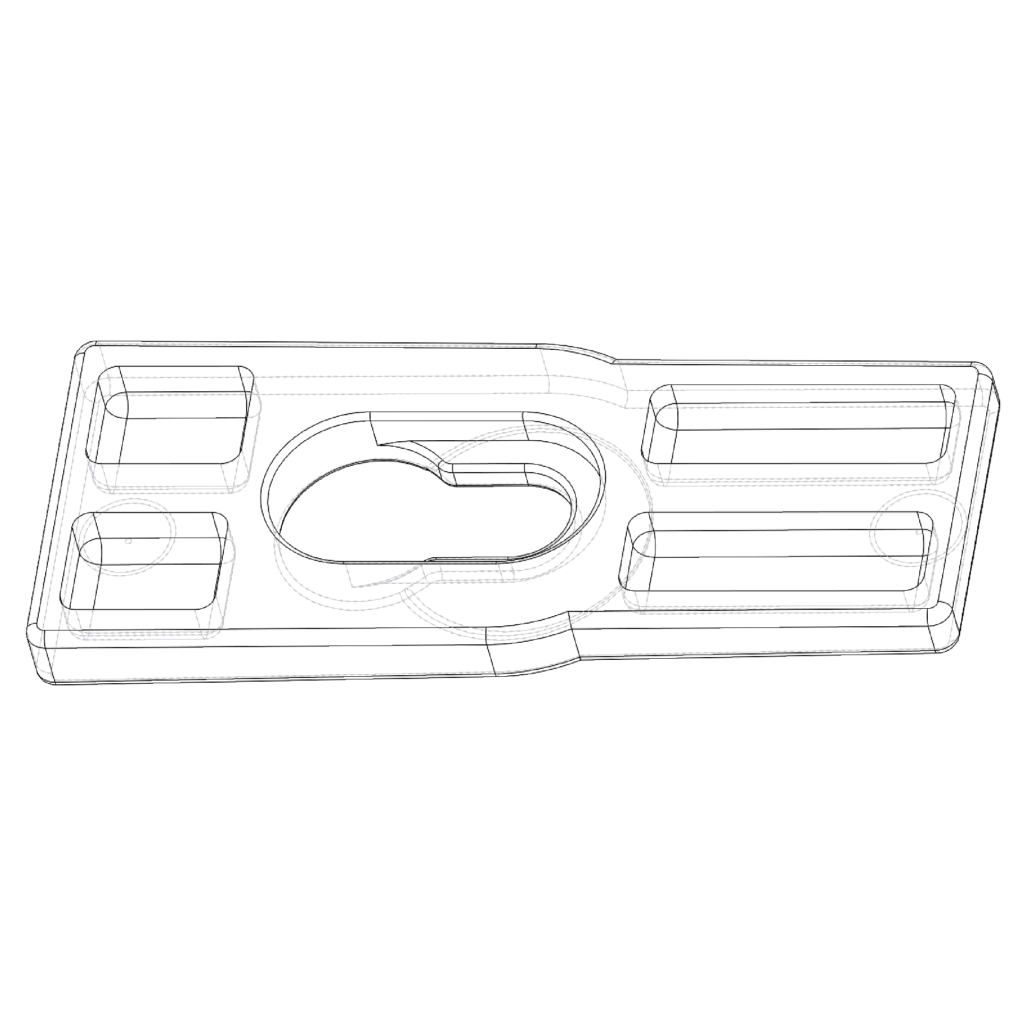

A seasoned engineer from a leader in the underwater robotics industry approached MPP with a formidable challenge—a 4-part (5-piece) assembly crucial for their underwater robotics application. However, the original parts, crafted from plastic, proved inadequate in the harsh and demanding underwater environments where their robotic platforms operated.

The company faced a dual challenge. They needed a partner who could transform these components into robust metal alternatives that could endure the challenging underwater conditions. Additionally, cost competitiveness was paramount, all while maintaining the precise repeatability the product demanded.

A leading company who works in underwater robotics

A seasoned engineer from a leader in the underwater robotics industry approached MPP with a formidable challenge—a 4-part (5-piece) assembly crucial for their underwater robotics application. However, the original parts, crafted from plastic, proved inadequate in the harsh and demanding underwater environments where their robotic platforms operated.

The company faced a dual challenge. They needed a partner who could transform these components into robust metal alternatives that could endure the challenging underwater conditions. Additionally, cost competitiveness was paramount, all while maintaining the precise repeatability the product demanded.

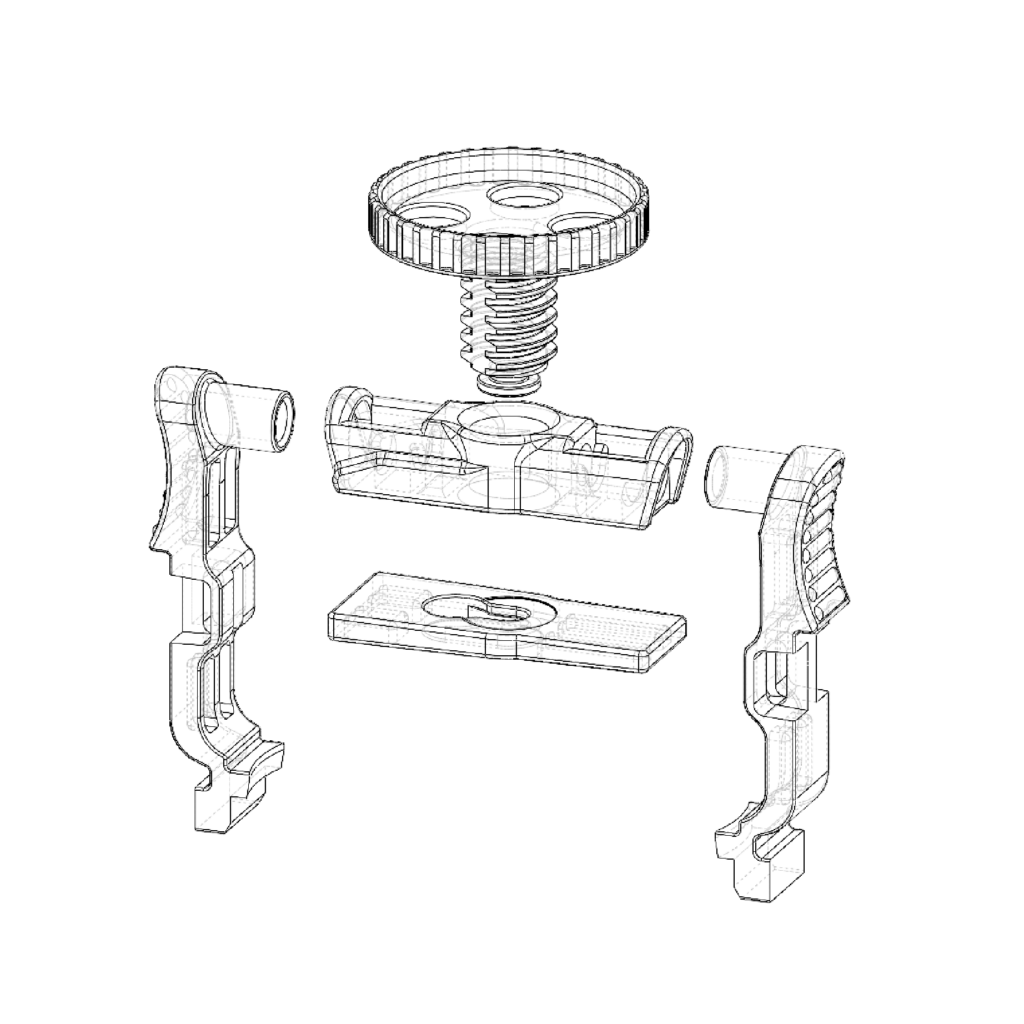

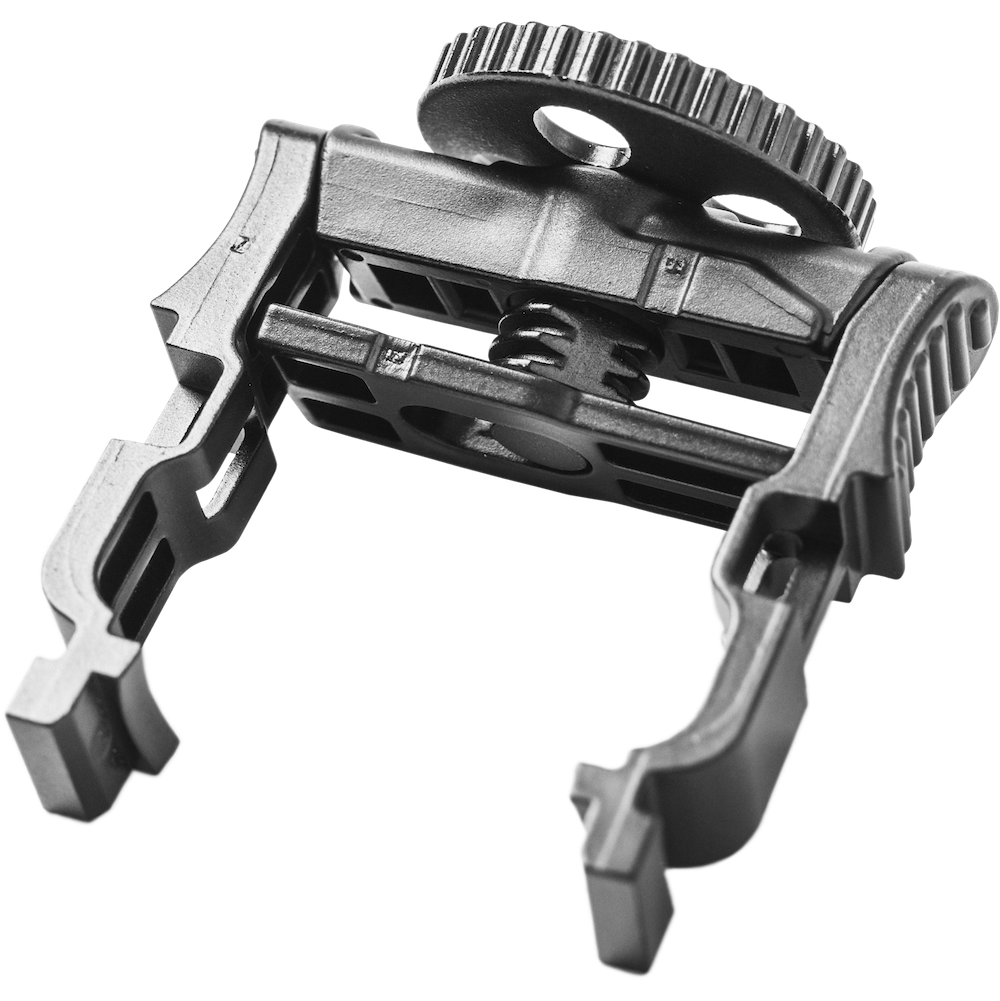

Our technical team engaged in thorough design reviews, collaborating closely with the company's own designer to refine and adapt the designs for Metal Injection Molding (MIM). The primary goal was clear: to minimize secondary operations and provide parts ready for seamless integration into the customer’s units. With only one in-house machining operation and one external coating operation required, these components left our facilities as complete assemblies, streamlining the customer’s assembly process.

MPP’s innovative approach extended to tooling as well. To maximize efficiency, we produced all four parts using a common family tool with a switch gate design. Leveraging our in-house feedstock production capabilities, we conducted material trials, ultimately selecting a material with a coating that exceeded the customer’s stringent requirements. In the manufacturing process, MPP employed open-close tooling to produce the thumb screw and the specified ACME-style threads. We also developed a robust machining operation to precision-cut internal ACME threads into the crossbar, ensuring the highest quality end product.

Exceeding customer requirements

The partnership with MPP not only met but exceeded the customer’s expectations, eliminating the need for iterative prototypes. Our tooling approach substantially reduced the customer’s overall expenses, delivering cost savings of approximately 75%. This unique and cost-effective approach made our technology accessible and paved the way for a seamless transition to metal components.

In recognition of these extraordinary efforts, MPP was honored with an Award of Distinction by the Metal Powder Industries Federation for this project.