Experience Unmatched Precision with MPP’s Gerotor Pump Solutions

Gerotors are vital components in fluid power systems and engines, known for their efficiency and reliability in fluid transfer applications. At MPP Innovations, we specialize in the design and manufacturing of high-quality gerotors, leveraging advanced technologies and materials to meet the diverse needs of our customers.

What Makes Gerotors the Superior Choice?

Discover the advantages:

Struggling with Energy Loss and High Operating Costs? Gerotors minimize internal leakage, delivering higher efficiency than other pump types. This means reduced energy consumption and significantly lower operating costs over time.

Facing Space and Weight Constraints in Your Systems?Gerotors offer a compact design, making them the ideal solution for tight spaces and weight-sensitive applications like automotive transmissions and hydraulic systems.

Dealing with Noise and Vibration in Critical Systems? Gerotors ensure smooth and consistent fluid delivery, minimizing vibration and noise—perfect for applications requiring quiet operation, such as vehicle power steering systems.

Need a Pump Solution That Handles High Pressures and Versatility? Gerotors operate at pressures up to 1,000 PSI and efficiently pump both liquids and gases, making them ideal for a wide range of industrial and commercial applications.

Design and Function

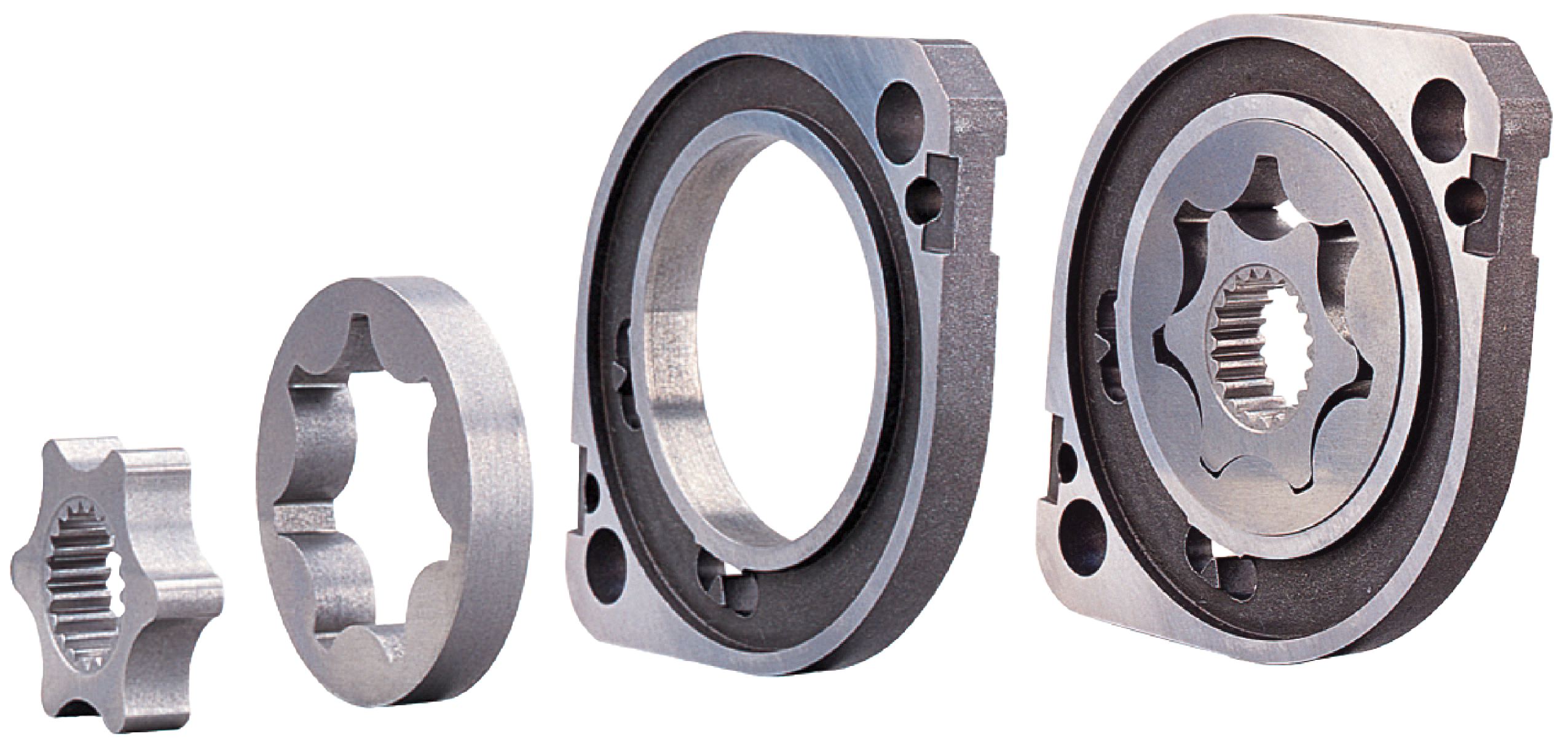

Originating in the late 19th century and continuously refined, gerotors offer a solution to common issues in fluid transfer and hydraulic systems. As a positive displacement pump system featuring an inner and outer rotor, gerotors provide efficient, reliable, and versatile performance. They ensure smooth fluid displacement with reduced noise and vibration.

Notably, gerotors require less input horsepower, contain fewer parts, and maintain exceptional performance at high speeds compared to other pump types, addressing efficiency and maintenance challenges effectively.

Tailored Gerotor Pump Solutions for Industry Challenges

At MPP Innovation, we specialize in developing gerotor pump solutions meticulously engineered to address the specific challenges of your industry applications. Our team is dedicated to overcoming operational complexities by delivering customized assemblies and designs that enhance system efficiency and reliability.

Our Custom-Engineered Solutions Include:

- Multiple Piece Assemblies: Designed to ensure seamless integration and optimized performance across diverse operational environments.

- Flexible Gerotor Designs: Customizable to perfectly fit within existing setups or engineered from scratch for new applications, enhancing system compatibility and functionality.

- PM Housings and Porting: Tailored Powder Metallurgy housings and precise porting options crafted to improve the mechanical and fluid dynamics of your systems.

- Specialized Applications: Advanced pump assemblies specifically developed to meet the rigorous demands of applications ranging from hydraulic systems to EV cooling technologies.

From enhancing hydraulic pump operations to optimizing cooling electronics and battery systems in electric vehicles, our solutions are focused on solving the unique challenges faced in each application. By providing robust, precision-engineered gerotor components, we help ensure your systems operate at peak efficiency and reliability

Industries

Automotive/Lubrication

We offer cost-effective gerotor pumps suitable for a broad spectrum of applications, including lubrication systems, fluid transfer, and high-performance cooling, critical for automotive applications.

Industrial Applications

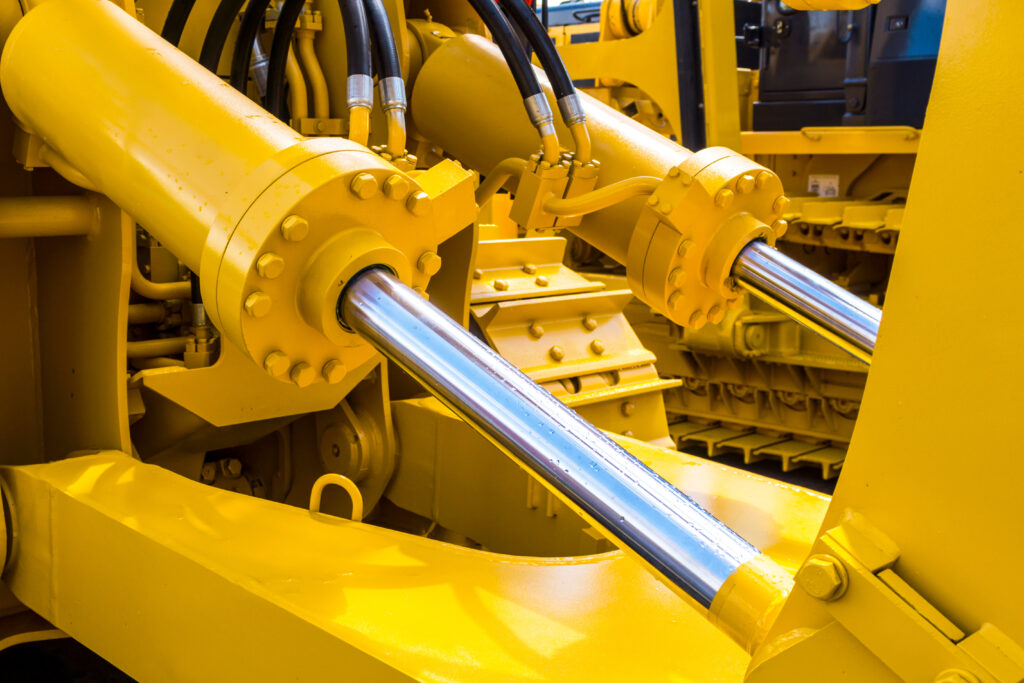

Our gerotors are integral to the efficient operation of hydraulic pumps, cooling systems, and vacuum pumps, ensuring reliability across various industrial settings.

Fluid Power

Our gerotor hydraulic motors and pumps are meticulously engineered for optimal performance, boosting efficiency and reliability in hydraulic system

Charge Flow Enhancement

Gerotor components are expertly designed to optimize charge flow, significantly enhancing system functionality and performance, making them essential for managing energy within complex systems.

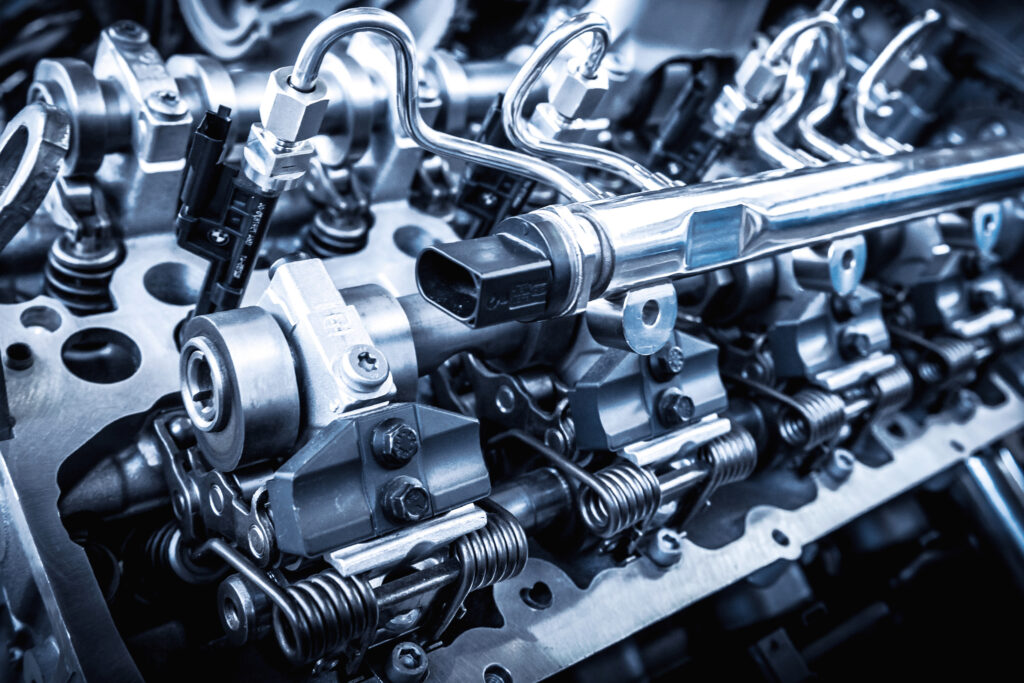

Fuel Systems Efficiency

Specifically engineered for fuel systems, our gerotor fuel pumps deliver fuel consistently and efficiently. This design ensures high performance and reliability, crucial for maintaining optimal engine operations.

By leveraging our extensive expertise and cutting-edge technology, we deliver gerotor solutions that not only meet but exceed the performance expectations of our clients across diverse sectors.

Facing the challenges of costly and complex manufacturing processes?

Our Powdered Metallurgy (PM) technique streamlines the production of gerotors, merging cost-effectiveness with high performance.

This method allows for intricate designs and tight tolerances essential for durable, high-performing pump components, providing significant design and cost advantages over traditional manufacturing approaches.

Elements to consider when designing the correct gerotor for your application include the following:

- Outside diameter requirement

- Width requirement

- Shaft size and speed

- Pumping media

- Operating temperature

- Operating pressure

- Pump displacement or flow requirement

Want to learn more about how

powder metallurgy works?

Advantages of Powder Metallurgy

Struggling with the high costs and limitations of traditional manufacturing methods for complex gerotor designs? Powder metallurgy offers a robust solution tailored to your specific gerotor needs. This technology not only facilitates the production of intricate shapes through net-shape capabilities but also reduces production costs and enhances efficiency.

Key Benefits of Powder Metallurgy for Gerotors:

- Precision Engineering: Achieves quieter operations through meticulous design.

- Tighter Tolerances: Ensures peak performance, crucial for optimal gerotor functionality.

- Cost Reduction: Offers a more economical alternative to traditional casting, particularly in tooling expenses.

- Complex Design Capability: Allows for the creation of complex forms without the need for extensive machining.

- Consistent Quality: Delivers part-to-part consistency, enhancing overall reliability of the components.

- Sustainable Practices: Minimizes scrap losses, promoting a more environmentally friendly manufacturing process.

Embrace powder metallurgy to overcome the challenges of producing high-quality, complex gerotor designs while maintaining cost efficiency and operational excellence.

Struggling to Find the Right Gerotor Partner?

With only a handful of trusted gerotor designers and manufacturers worldwide, choosing the right team is critical. At MPP, our engineers are ready to solve your toughest challenges—whether you’re integrating gerotors for the first time or optimizing existing applications. Don’t settle for less—partner with the experts to design a precision PM solution that meets your exact needs.

NEED A COMPLETE SOLUTION, NOT JUST PARTS?

At MPP, we go beyond gerotor component manufacturing to deliver full-system solutions that improve efficiency and performance. From pump components and gerotor housings to port plates and surrounding parts, we provide everything you need to optimize your systems and streamline operations.