If you’ve ever baked a cake from scratch, you already understand the fundamentals of Powder Metallurgy (PM). Each ingredient in a cake mix has a purpose: flour for structure, sugar for sweetness, eggs for binding, and baking powder to help it rise. When mixed and poured into a pan, the batter takes shape. Then, as it bakes, heat transforms it into a solid, uniform cake – wasting no material. Every element contributes to the final product.

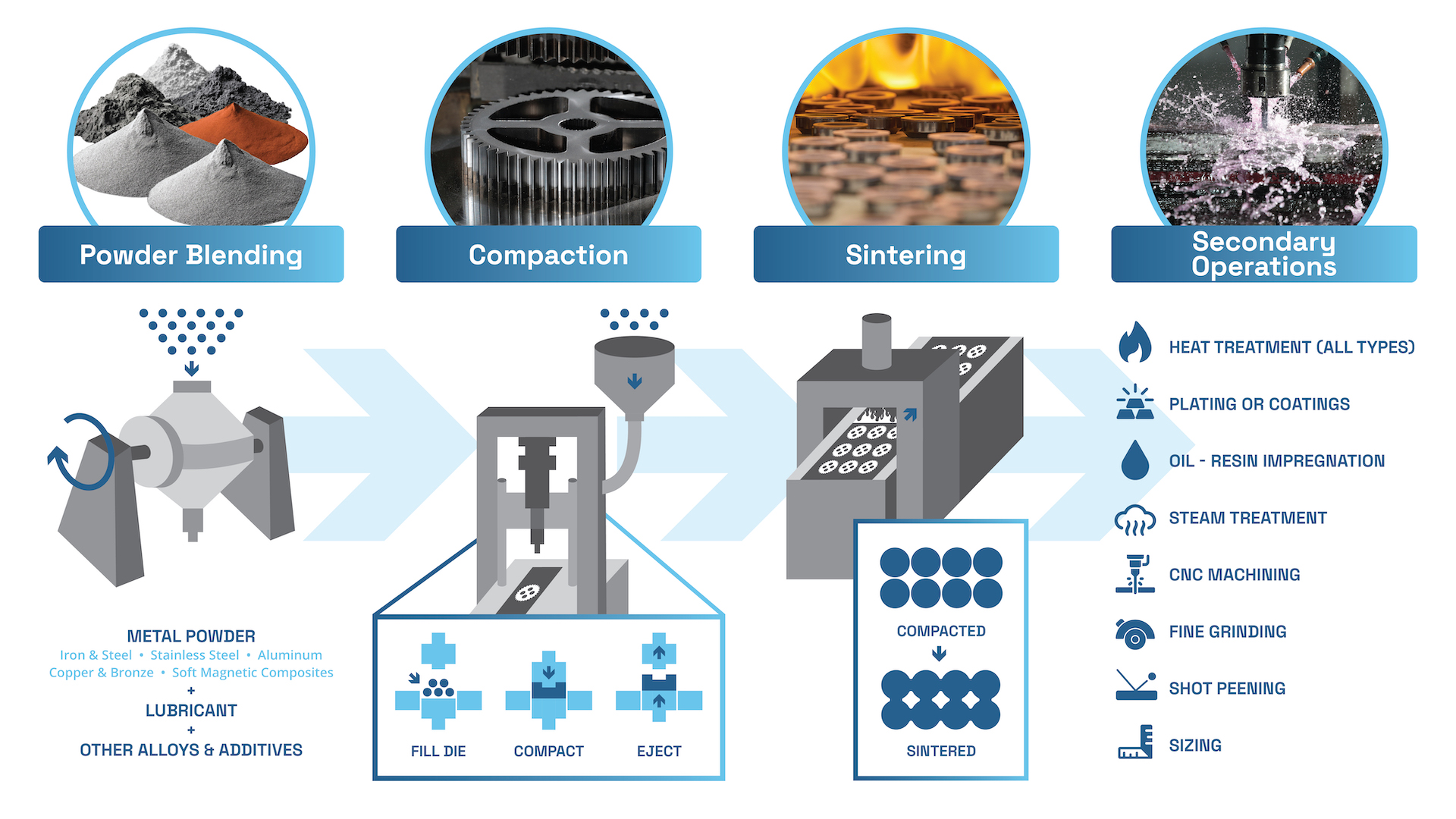

Powder Metallurgy follows a similar process. It begins with a carefully measured blend of fine metal powders fed into a mold, much like pouring cake batter into a pan. But instead of simply holding its shape, the powder is compacted under extremely high pressure, forming a solid structure. Then, through sintering, a process akin to baking, the particles bond at a microscopic level, creating a dense, durable component. The result? A precision-formed part manufactured with minimal waste – just like a perfectly baked cake.

Why Choose Powder Metallurgy?

- Minimal Waste: The Powder Metallurgy (PM) process utilizes 95-98% of raw material, while traditional machining can waste 50-80% of metal chips. That’s a significant cost advantage – less material lost means lower expenses and a more sustainable process.

- Faster Production & Greater Efficiency: Since PM produces near-net shape components, it eliminates many secondary machining steps. This leads to shorter lead times, higher consistency, and reduced labor costs.

- Enhanced Material Strength & Customization: PM allows for precise control over material composition, ensuring uniform density and strength. Need added durability? Custom alloy blends can be incorporated to enhance performance.

- Cost-Effective & Consistent: Once tooling is in place, PM enables repeatable, high-precision manufacturing, reducing unit costs and ensuring consistent quality across large production runs.

Is Powder Metallurgy the Right Fit for Your Application?

Explore how MPP PM capabilities can address your production challenges by delivering durable, precise components that are more cost-effective. With our expertise in Metal Injection Molding Services and Advanced Metallurgical Engineering, MPP Innovation provides high-quality, tailored solutions that perfectly align with your specific requirements across various sectors, including Automotive, Medical Equipment, and Off-Highway Vehicles. Discover the benefits of partnering with a powder metal industry leader committed to innovation and environmental sustainability.