Next Generation Axial Flux Motor

Torev Motors (TM)

an emerging innovator in the electric vehicle (EV) market.

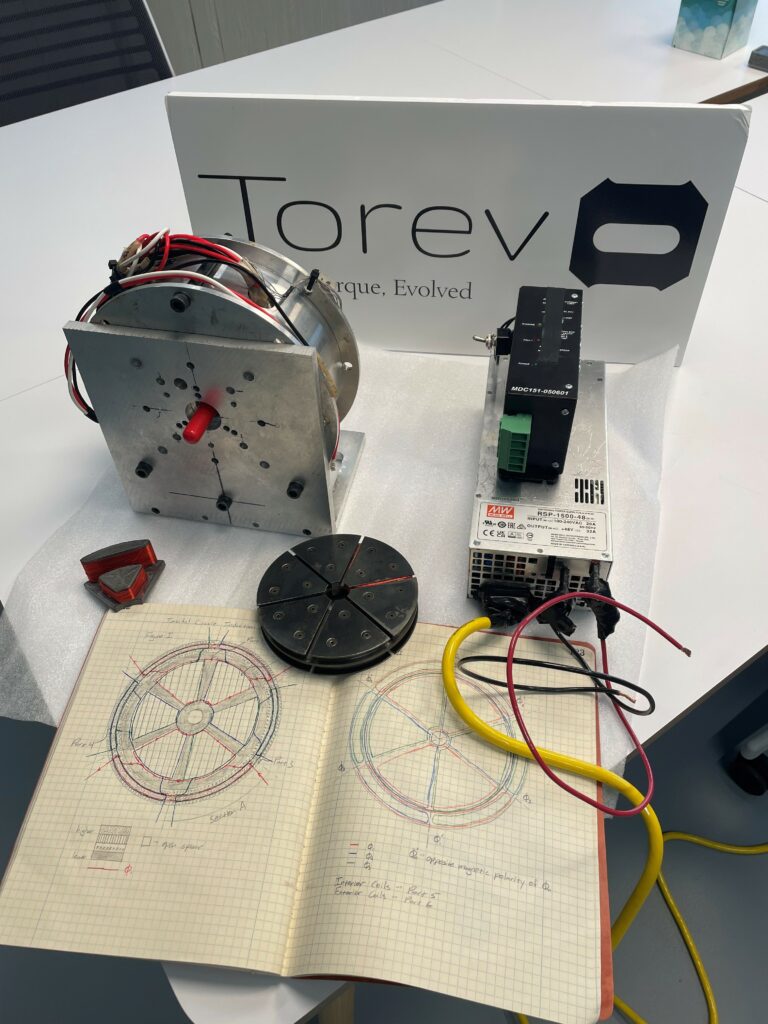

At the Battery and EV Tech Expo, Torev Motors approached MPP with a visionary goal: to develop a high-power dense axial flux motor that would reduce reliance on rare earth materials, deliver high torque at low RPMs, while achieving high efficiency in their applications. This required a breakthrough in motor design and material usage to meet the demands of the modern EV market and the needs of Torev Motors.

Axial flux stator cores are ideal for SMC materials as they take advantage of 3D flux. Manufacturing a laminated AF stator core requires many additional manufacturing steps and machining processes due to the geometry of the AF stator cores. The dimensional accuracy of the powder metal process allows the stator cores tooth to tooth accuracy facilitating preformed windings reducing the use of magnetic materials as compared to laminated designs.

Torev Motors (TM)

an emerging innovator in the electric vehicle (EV) market.

At the Battery and EV Tech Expo, Torev Motors approached MPP with a visionary goal: to develop a high-power dense axial flux motor that would reduce reliance on rare earth materials, deliver high torque at low RPMs, while achieving high efficiency in their applications. This required a breakthrough in motor design and material usage to meet the demands of the modern EV market and the needs of Torev Motors.

Axial flux stator cores are ideal for SMC materials as they take advantage of 3D flux. Manufacturing a laminated AF stator core requires many additional manufacturing steps and machining processes due to the geometry of the AF stator cores. The dimensional accuracy of the powder metal process allows the stator cores tooth to tooth accuracy facilitating preformed windings reducing the use of magnetic materials as compared to laminated designs.

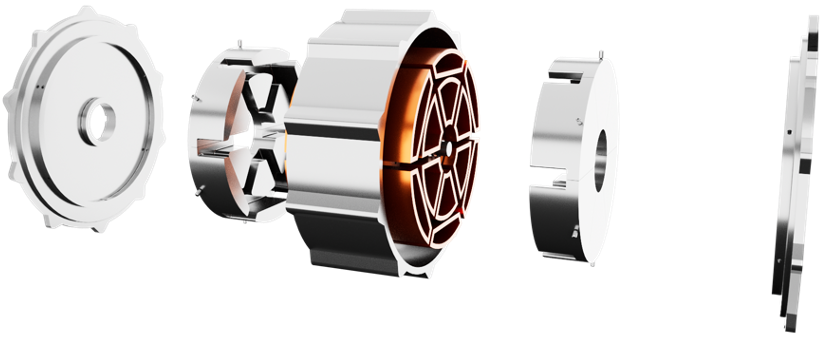

Through a collaborative effort, Torev Motors and MPP embarked on designing a prototype stator for the axial flux motor. Utilizing MPP's advanced Soft Magnetic Composite (SMC) technology, the team developed a patented stator structure that was the first of its kind.

The stator design, made using SMC materials, was one-third the length of traditional radial flux motor, making it more compact and lightweight. Additionally, the stator was molded as a single component, simplifying manufacturing.

Once the design was approved, it was time to manufacture the stator. SMC materials offer significant magnetic benefits for applications operating at higher frequencies. The insulation layers in SMC materials lower eddy currents, which proved to help the motor remain cooler for longer, thereby extending battery life. The use of less rare earth materials made the solution more sustainable, reducing waste in comparison to laminated designs.

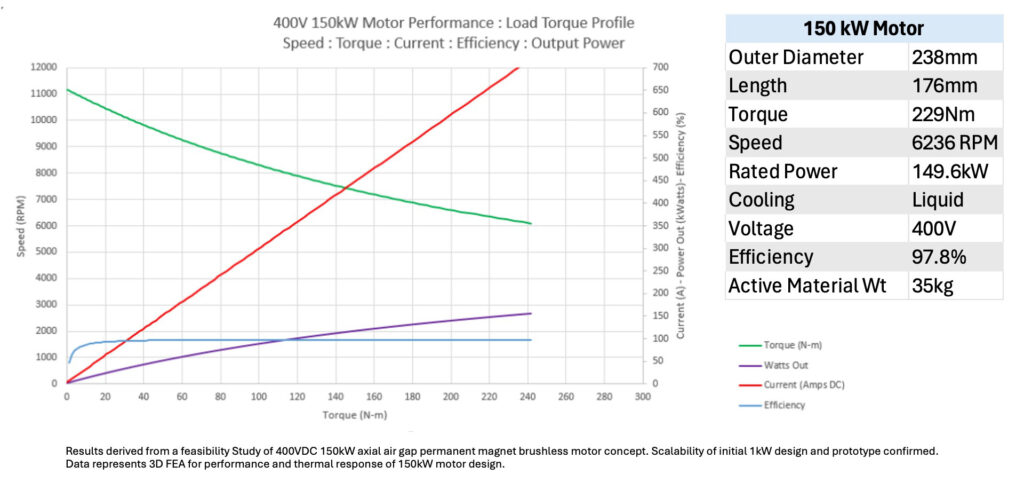

The partnership resulted in a high power dense axial flux motor. The innovative design enabled more active power generation and featured a highly modular approach. The solution simulations show an astounding 98% peak efficiency in 150 kW motors, significantly enhancing the system optimization for Torev Motors’ EV solutions. Overall, the axial flux motor led to:

- Enhanced Performance: Leveraging 3D flux technology, the stator achieved optimized magnetic field distribution, enhancing torque production and efficiency across lower operating speeds in the motor.

- Cost Reduction: Simplifying manufacturing through its innovative modular design and reducing rare earth magnets contributed to 30% lower production costs.

- Lightweight and Compact: The axial flux motor’s compact size, saving 30% in overall weight, made it ideal for modern applications, contributing to better vehicle performance and energy efficiency.

The advanced motor design with SMC technology proved suitable for a range of product uses.

Transportation

airport tugs, golf carts

Marine

pod propulsion systems, water sports equipment

eAxle Sub-Assembly

EV autos and trucks

Industrial

HVAC pumps and hydraulics, robotics