Simplifying Cam Assemblies with Powder Metallurgy

A Global Power Management Company

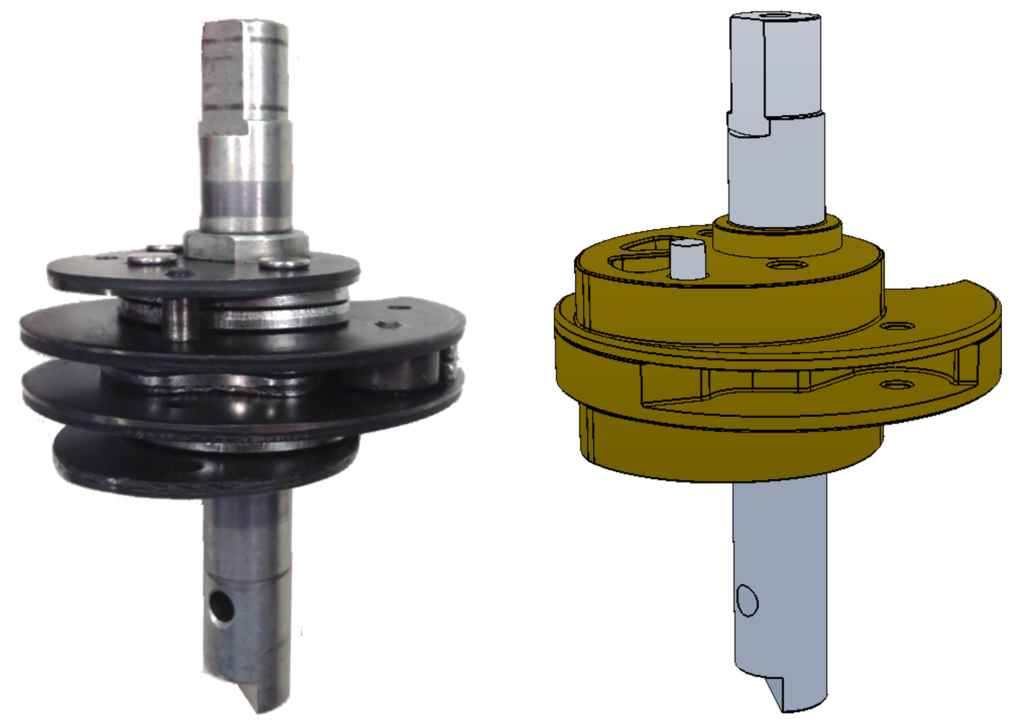

An engineer from a global power management company specializing in energy-efficient solutions for managing electrical, hydraulic, and mechanical power approached MPP with a significant challenge. Their current design - a 10-piece steel stamping assembly on a hardened steel shaft- had become frustrating. The complexity of the assembly led to excessive tooling costs, alignment issues, and premature wear.

Seeking alternatives, the engineer considered a stainless steel, heavily machined, heat-treated casting. However, this option proved equally problematic due to:

- High material and machining costs.

- Lot-to-lot distortion requires rework.

- Multiple machining and heat-treatment processes cause lengthy production times.

The customer was in production but faced rising costs, quality issues, and scheduling delays. They needed a solution to simplify the assembly, improve performance, and significantly reduce costs.

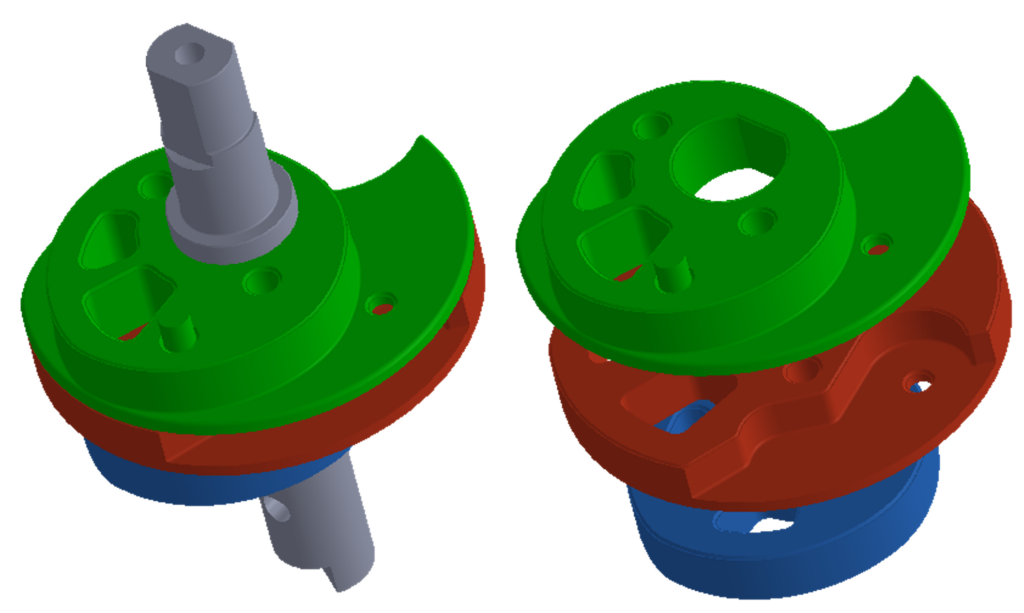

Our team partnered with the customer to reimagine the design using powder metallurgy. Through design collaboration and our Conversioneering® process, we replaced the 10-piece steel stamping assembly with a streamlined three-piece powder metal component.

This solution addressed all the customer’s pain points:

Simplified Design: 3 piece components replaced the original 10, reducing assembly complexity and improving reliability.

Enhanced Performance: Powder metallurgy offered better wear surfaces and impact resistance, resolving alignment and durability issues.

Cost-Effective Production: Near-net-shape manufacturing eliminated the need for extensive machining, significantly lowering tooling and material costs.

In engineering, it’s easy to over-complicate designs in search of perfection. However, as this case demonstrates, simplicity is often the ultimate innovation. Powder metallurgy didn’t just replace an existing solution; it opened a new way of thinking that prioritizes efficiency, performance, and cost-effectiveness.

- Unmatched Precision: The cam profile was flawlessly aligned, with wear surfaces engineered to thrive in demanding applications.

- Streamlined Efficiency: A cumbersome 10-piece assembly was reduced to just three components, eliminating failure points and simplifying production.

- Enhanced Strength: Powder metallurgy delivered superior impact resistance and durability, outperforming expectations during overload testing.

- Significant Cost Savings: The new assembly slashed total costs by 45% by minimizing material waste and reducing tooling needs.

Most importantly, this wasn’t just a solution for one project—it was proof that powder metallurgy can fundamentally transform complex designs, redefining what’s possible in manufacturing.