Revolutionizing Accessibility in Medical Devices with Metal Injection Molding (MIM)

Tactile Engineering

an Indiana-based startup developing advanced assistive technologies.

To bring the Cadence Tablet to market, Tactile Engineering needed a manufacturing partner with deep expertise in metal injection molding for medical devices. The core plate required:

Exceptional flatness and dimensional stability

Non-magnetic properties

Tight tolerances

Material consistency at scale

These characteristics ruled out conventional machining and casting methods. Tactile Engineering turned to MPP’s advanced MIM capabilities for a scalable, repeatable solution.

Tactile Engineering

an Indiana-based startup developing advanced assistive technologies.

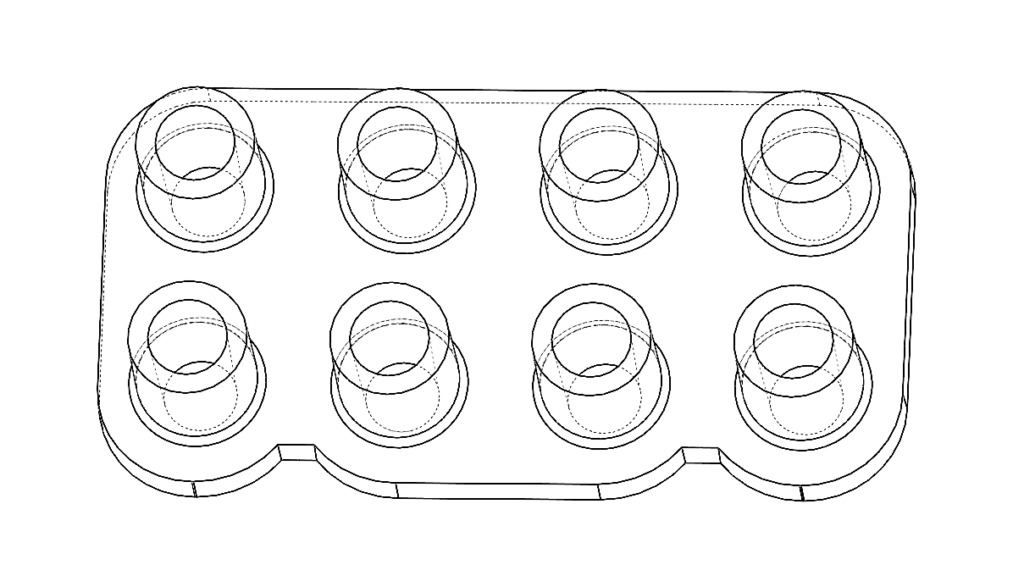

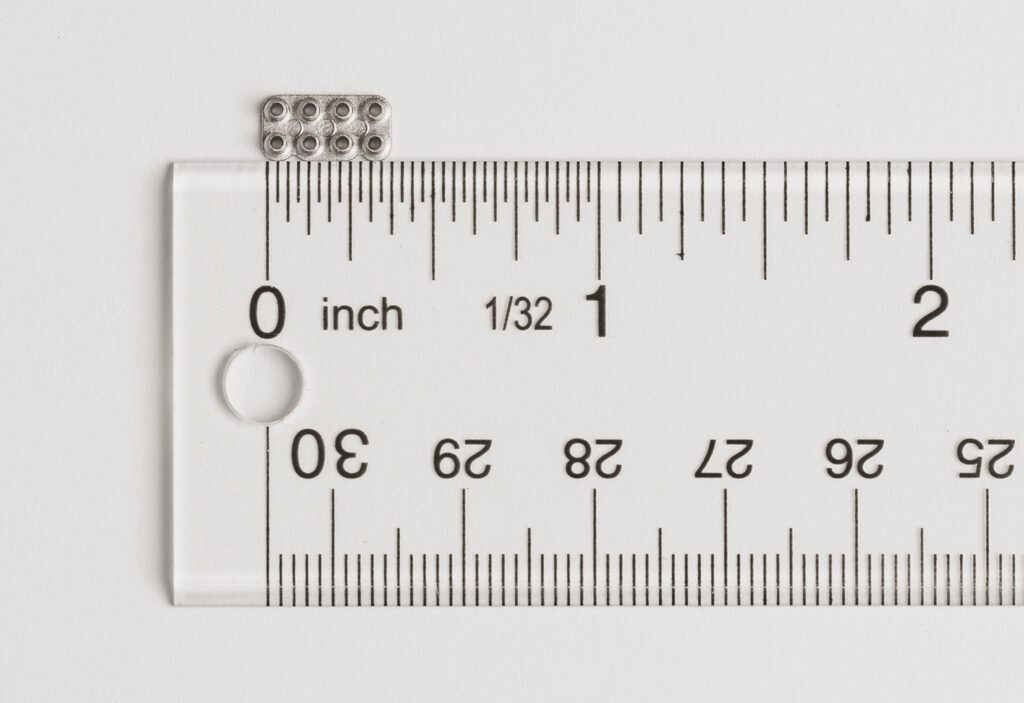

Tactile Engineering approached MPP seeking a solution for producing the Core Plate for their Cadence Tablet, a dynamic braille reader for the blind and visually impaired. The product had specifications (precise, flatness, and non-magnetic characteristics, etc.) that required a new approach to Metal Injection Molding manufacturing MPP was ready to take on.

MPP collaborated closely with Tactile Engineering to design and produce the core plate using 17-4 PH stainless steel, in compliance with MPIF Standard 35. By leveraging proprietary MIM feedstock formulations and process control, MPP delivered:

Consistent part geometry and flatness

Controlled magnetic permeability

Repeatable part quality at high volumes

Full traceability and materials compliance for medical device standards

This approach enabled complex geometries and tight tolerances while maintaining the performance and regulatory requirements of a high-tech medical device.

For our customer:

The transition from traditional manufacturing methods to MIM technology resulted in a significant reduction of 40% in waste and 10X in cost savings per piece for Tactile Engineering. Additionally, the solution simplified manufacturing and enhanced efficiency in their assembly process.

For the market:

The Cadence Tablet revolutionizes accessibility for the blind and visually impaired, making it the first tactile device to display tactile graphics that move and change beneath a user’s fingers. This device opens opportunities for individuals with disabilities to interact and experience live events, entertainment, and access dynamic content, textbooks, and collaborative tools. The Cadence Tablet reduces accommodation costs, enhances educational and professional opportunities, and improves quality of life for an underserved population.

View how the Cadence Tablet will help the vision impaired experience the eclipse.

New Component Design and Conversioneering

MPP is an industry leader in metal injection molding (MIM) and powder metallurgy, with a proven track record of delivering precision-engineered components for the most demanding applications.

Award-winning capabilities: MPP was honored with the 2024 MPIF Grand Prize for our innovative MIM core plate used in the Cadence Tablet—a breakthrough device for the visually impaired.

Expertise in complex geometries and tight tolerances

In-house design, engineering, and materials support

U.S.-based manufacturing for supply chain reliability and fast turnaround

Collaborative partnerships that take products from prototype to scalable production

Whether you're developing next-gen medical devices, micro components, or multi-functional assemblies, MPP has the depth of experience and innovation to bring your vision to life.