The electric vehicle (EV) industry is constantly innovating, driven by the need for efficiency, sustainability, and superior performance. It is no surprise that electrification is causing many industries to start thinking about how they can create EV applications that are efficient in both cost and performance.

Central to this is the emergence of novel motor designs, particularly axial flux motors, which harness the capabilities of Soft Magnetic Composites (SMCs) and powdered metal solutions to revolutionize traditional motor technology.

Understanding Powdered Metallurgy

Powdered metallurgy (PM) is a process that involves creating solid parts from metal powders. The PM process offers numerous benefits, including net shape capabilities, minimal scrap, excellent surface finishes, and cost-effective, high-volume manufacturing. The process consists of blending atomized powder with alloys and lubricants, pressing the mixture in a die cavity, sintering the compacted pieces, and optionally adding secondary operations like heat treatment or machining.

MPP has been manufacturing electrical components for over 30 years. These components and materials include sintered iron, silicon iron, phosphorus iron, and a wide range of electrical copper materials. These components are used in demanding electrical applications such as switch gear and busbar assemblies, and they typically achieve up to 99% IACS conductivity values. Additionally, MPP manufactures high-volume automotive aluminum components for high-strength, lightweight, in addition to heat sink and electrical applications.

Introducing Soft Magnetic Composites

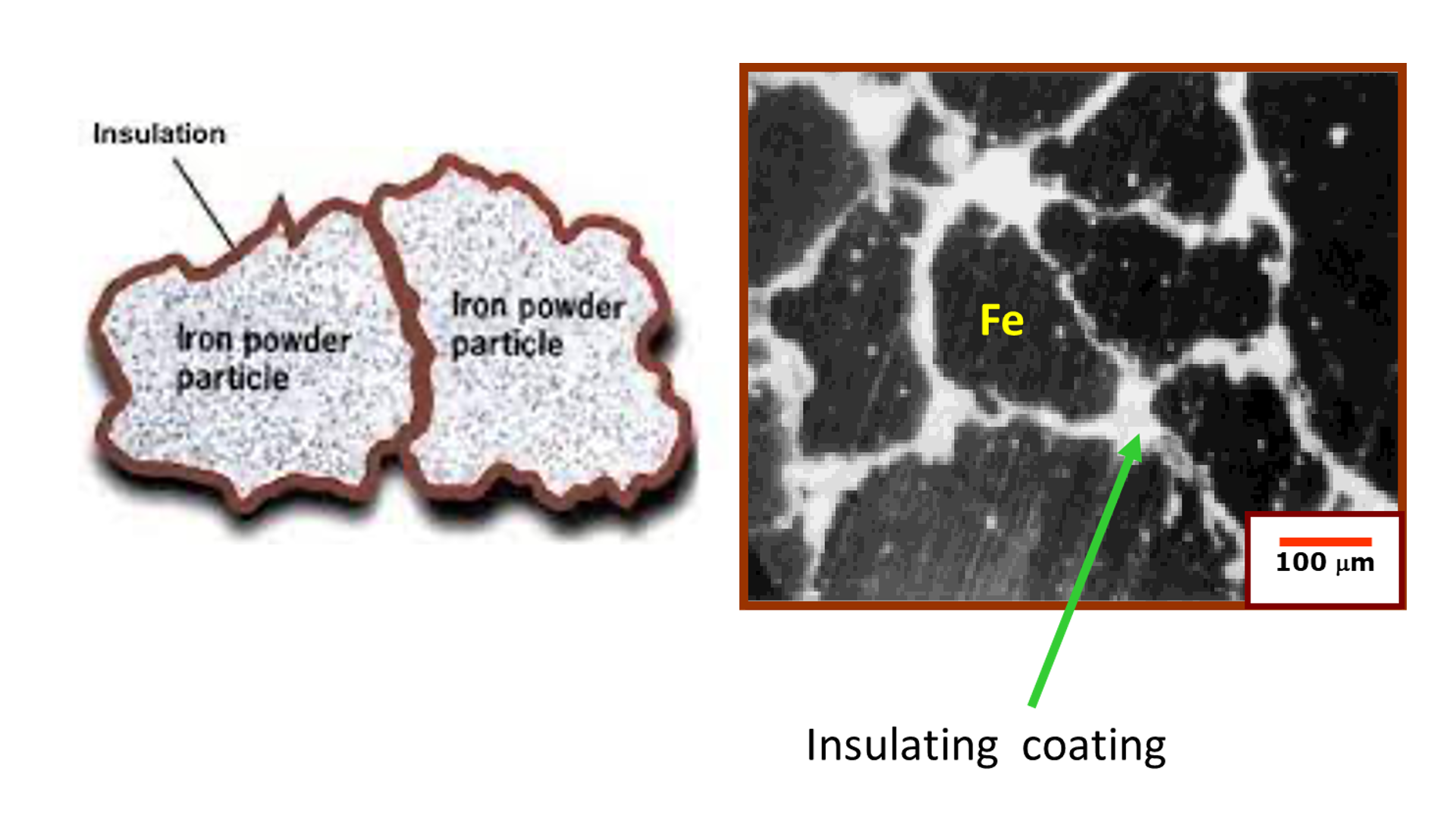

Soft magnetic composites are iron powder particles coated with an electrically insulating layer, designed to improve magnetic performance in AC motors and other electromagnetic parts.

SMCs utilize a similar process to traditional powdered metal, involving the pressing of coated iron powder particles into a die cavity and forming them into the desired shape. These components are then heat-treated, which is less energy-intensive than traditional sintering, resulting in parts with tighter tolerances and higher efficiency.

Advantages of using SMCs

SMCs offer numerous advantages over traditional laminated cores, including:

- High Electrical Resistivity: Reduces eddy current losses and improves efficiency in high-frequency applications.

- Three-Dimensional Magnetic Flux: Allows for innovative motor designs that reduce weight and size while increasing performance.

- Design Flexibility: Facilitates complex geometries that optimize magnetic flux and material utilization, leading to cost and weight reductions.

- Sustainability: Utilizes recycled materials and reduces the need for rare earth magnets, contributing to a more stable and environmentally friendly supply chain.

SMC materials, compared to silicon iron materials, reveal several key differences, particularly in permeability and efficiency at high frequencies. While SMCs require higher currents to generate the same torque at low magnetic field strengths, their three-dimensional design approach compensates for this. Notably, SMC materials exhibit reduced core losses at frequencies above 350 hertz compared to traditional 0.5mm laminations, enhancing energy efficiency by eliminating eddy currents. To maximize these benefits, SMC motor designs should be tailored from the start, leveraging their unique properties for lower core losses, minimal scrap, and compact assemblies.

SMC vs. Stacked Laminations

SMCs provide significant benefits over traditional stacked laminations. The key difference lies in their manufacturing process and resulting magnetic properties. SMCs are formed from iron powder particles coated with insulation, allowing for three-dimensional magnetic flux, which enhances performance in high-frequency applications. In contrast, stacked laminations, made from thin steel sheets, only allow for two-dimensional flux and are more prone to eddy current losses. This makes SMCs a superior choice for innovative motor designs that demand high efficiency and reduced weight.

Axial Flux Overview and Benefits

When talking about axial flux, there are many options for motor designers. Below are common configurations consisting of a 1) single stator, single rotor 2) double stator, single rotor 3) double rotor, single stator. The other thing that’s interesting about axial flux motors in these configurations is that they can be stacked, so you could have two of these in an application and it can take advantage of the high-power density.

Axial flux motors offer several advantages over traditional radial flux motors. These motors have a high power-to-weight ratio, delivering the same power in a significantly smaller package. This makes them ideal for applications where space and weight are critical considerations. Axial flux motors also use magnetic flux more efficiently, reducing energy loss and enhancing overall performance. Their design is adaptable, allowing for customization to meet specific requirements, such as single or multiple air gaps or yokeless stator configurations. These features make axial flux motors suitable for various industrial, auxiliary, and EV applications, offering higher efficiency and lower costs.

Real-Life Examples Using Soft Magnetic Composites: Why They’re the Perfect Fit for Axial Flux Motors

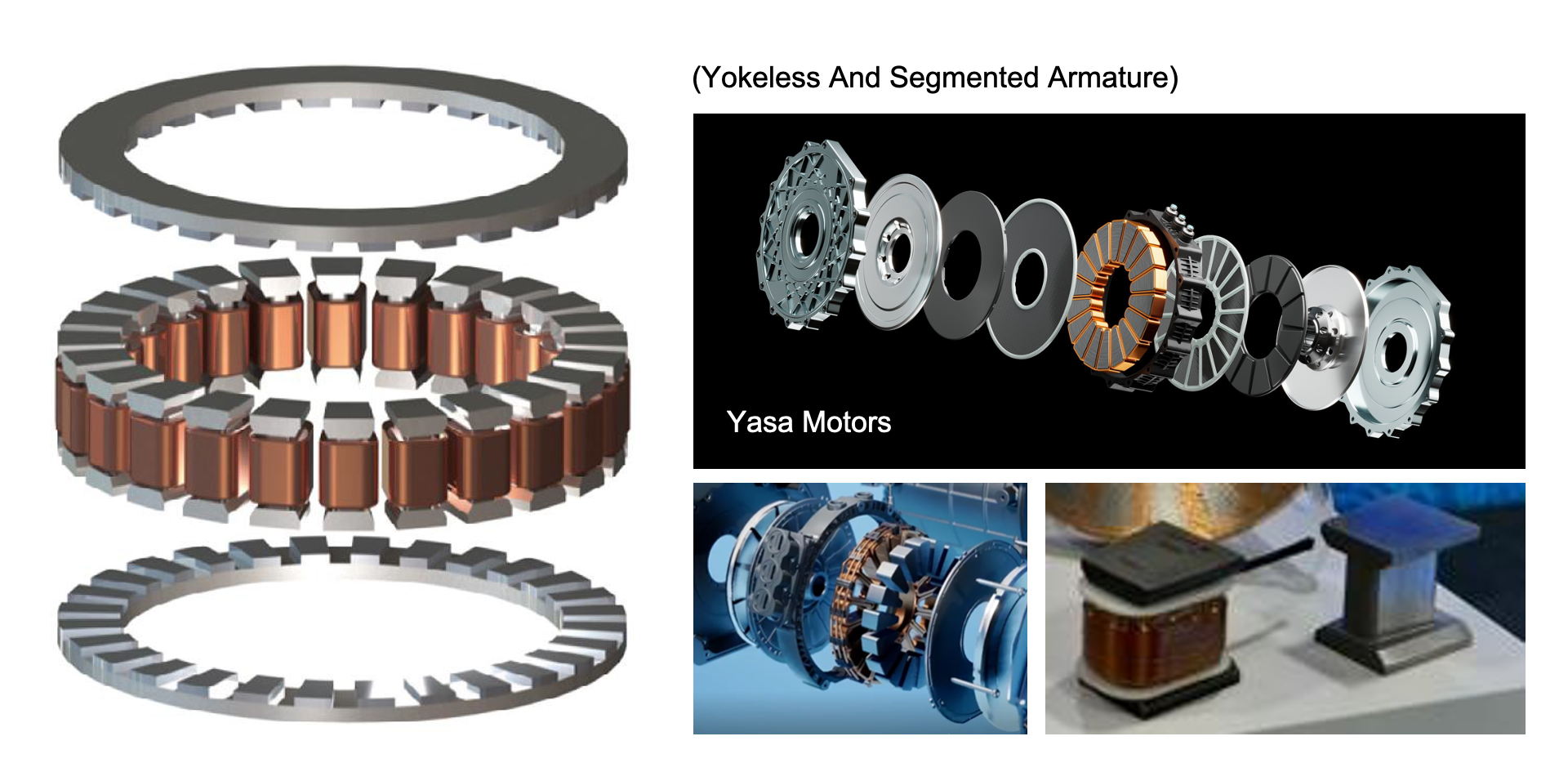

Yokeless and Segmented Armature (YASA)

Yokeless and Segmented Armature (YASA)

The YASA motor is renowned for its single-tooth yokeless design that reduces losses and enhances cooling. The motor has two rotors and one stator. This motor uses preformed windings and eliminates the losses typically associated with the yoke or back iron. The result is a compact, lightweight motor with a high power-to-weight ratio, ideal for traction motors and other high-performance applications.

Torev Motors Double Air Gap 150KW Motor

Torev Motors Double Air Gap 150KW Motor

Another innovative design is through our partnership with Torev Motors. This application involves high-torque, low-speed motors with two independent stator coils. They are on the same back iron and are wound in opposite directions, exerting additional force on the motor’s rotor magnets and providing increased torque. This design not only enhances efficiency and scalability but also leverages SMC’s benefits such as lower core losses, reduced weight, and improved energy efficiency, all while reducing reliance on rare earth magnets. This unique coil structure allows the motor to scale radially and axially, making it suitable for a range of applications. By turning off the outer winding during coasting or when not needed, these motors also save battery life, enhancing overall efficiency.

Axial Flux Induction Motor

Axial Flux Induction Motor

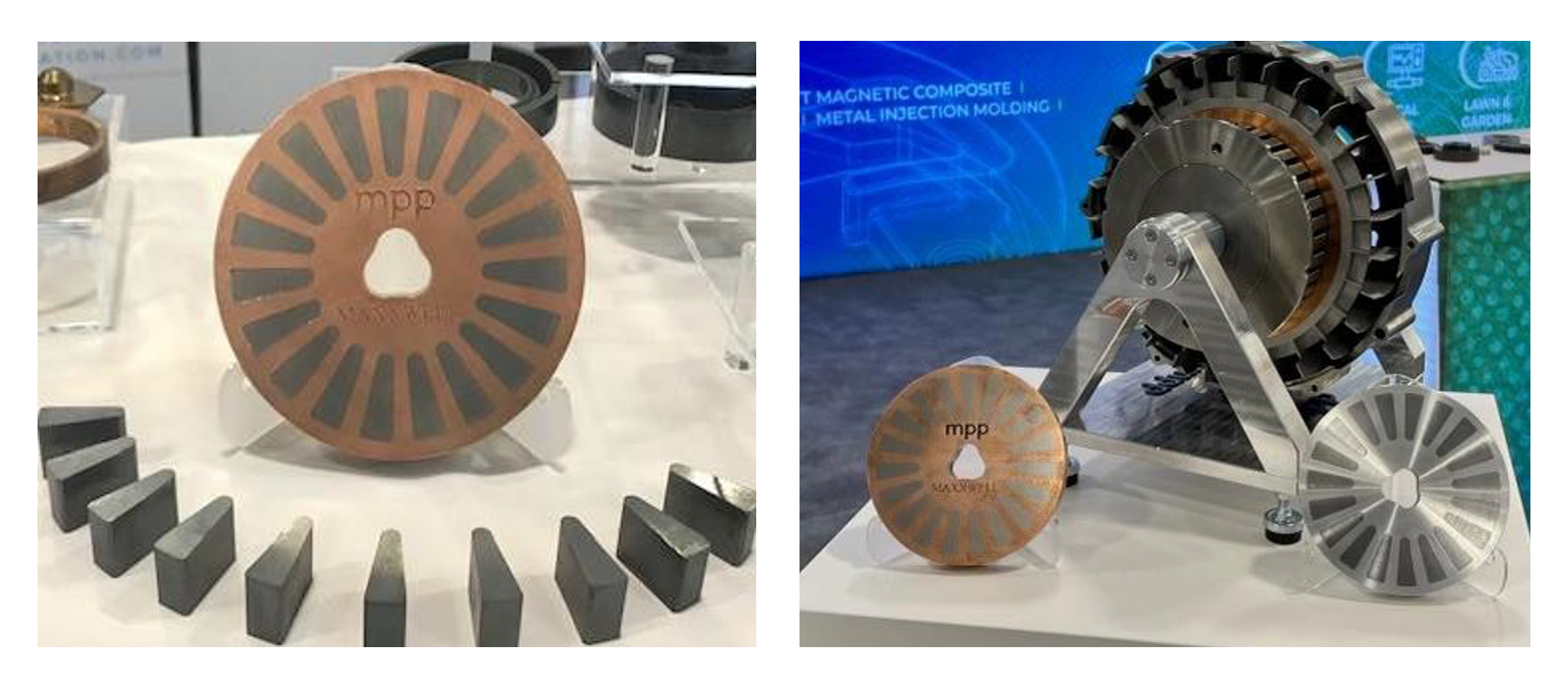

This axial flux induction motor eliminates permanent magnets or rare earth magnets. This motor feature rotors made from copper or aluminum powder, fused with SMC inserts, creating an induction rotor assembly that is cost-effective and lightweight. Such motors are perfect for applications requiring a stable supply chain without relying on rare-earth materials, like onboard vehicle generators, pumps, and e-bikes.

The Foundation of MPP’s Expertise

MPP has been a leader in the powdered metal industry for over 75 years, producing over 300 million parts annually and serving more than 500 customers across 40 countries. Sustainability is embedded in MPP’s DNA, with powdered metal originating from more than 95% recycled sources. This sustainable approach translates into a manufacturing process that requires 40% lower energy input and CO2 emissions compared to traditional methods.

Our goal at MPP is to work with motor designers from the early stages of project development to help maximize the utilization of SMC materials. We strive to tailor designs to leverage the unique properties of SMCs, such as three-dimensional magnetic flux and high material utilization. This collaborative approach ensures that the resulting motor designs achieve optimal performance, efficiency, and cost-effectiveness.

Collaboration and Optimization

Whether you are developing the next generation of traction motors or exploring new applications for axial flux designs, SMCs offer a pathway to achieving unprecedented efficiency and sustainability. Embrace the potential of soft magnetic composites and drive your EV motor innovations to new heights.