Advancing Electrification with Soft Magnetic Composites

Meet Rising Demand with Innovative Solutions

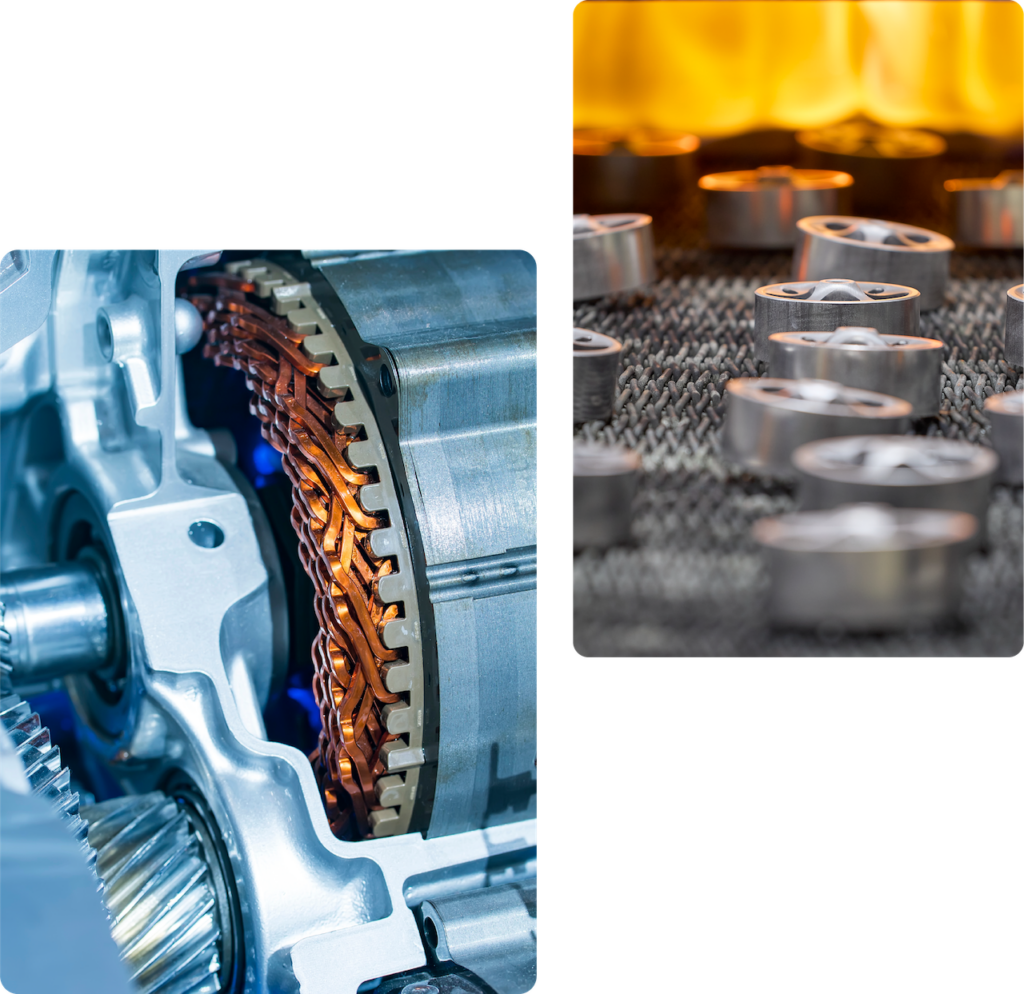

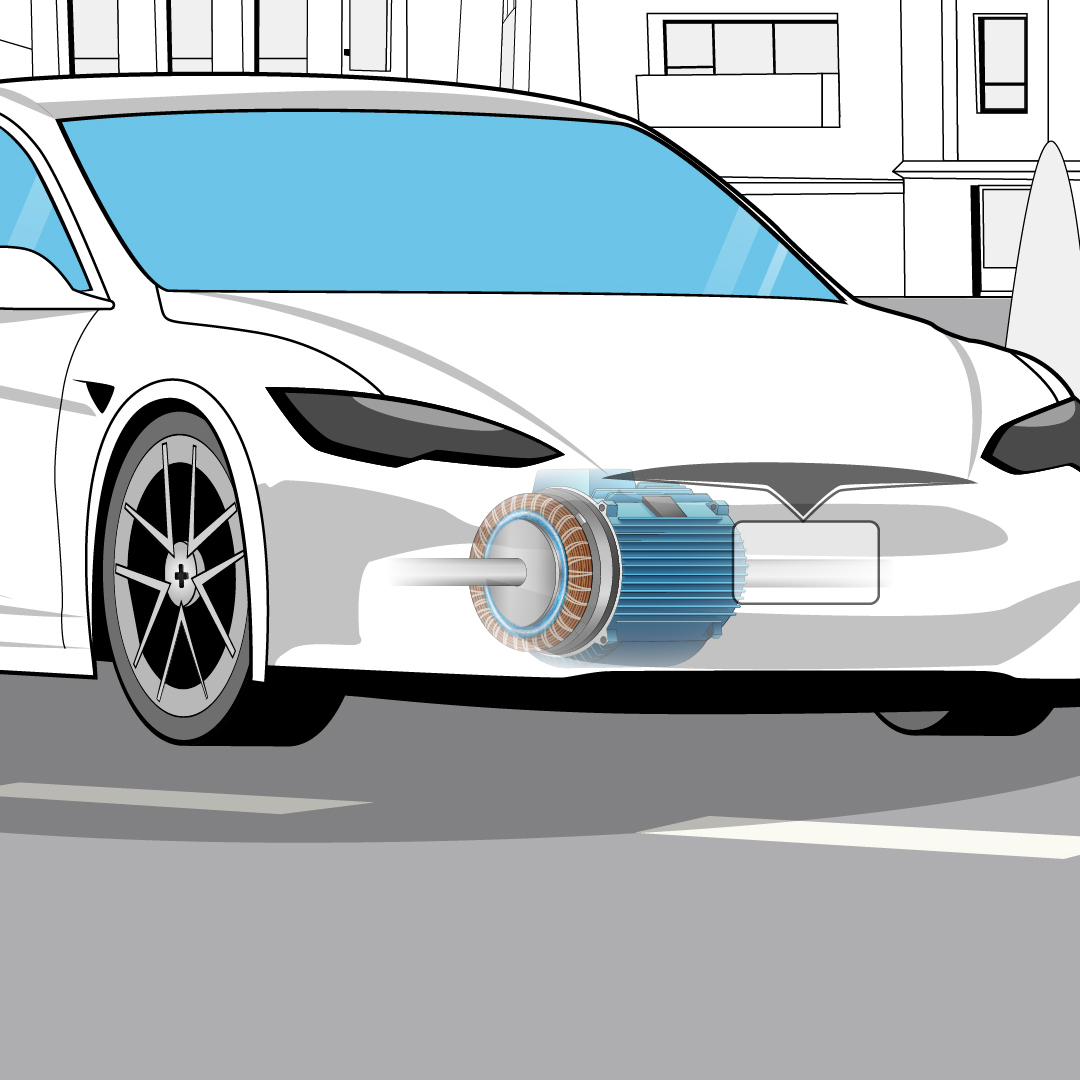

As the shift towards electrification accelerates, industries face pressure to adapt quickly and efficiently. Soft magnetic composites (SMCs) are pivotal in meeting these demands, especially in electric motor production. Their unique insulation coated powder particles allow for precise, single-press net shaping, streamlining the creation of lamination stacks essential for axial, radial and transverse flux motors.. With SMC technology, you can not only keep pace with the growing demand for advanced electric motors but also drive innovation in a rapidly evolving technological landscape.

How Soft Magnetic Composites Can Help Your Product Designs

As the leading provider of SMC parts, we apply our extensive knowledge and expertise to solve your specific challenges, delivering tailored Soft Magnetic Composite solutions that meet your unique requirements.

- Design Flexibility: SMC materials can be molded into any configuration, providing design freedom across diverse applications.

- Increased Energy Efficiency: By reducing eddy currents with our advanced insulation layers, SMCs reduce frequency-dependent losses, boosting the energy efficiency of your projects.

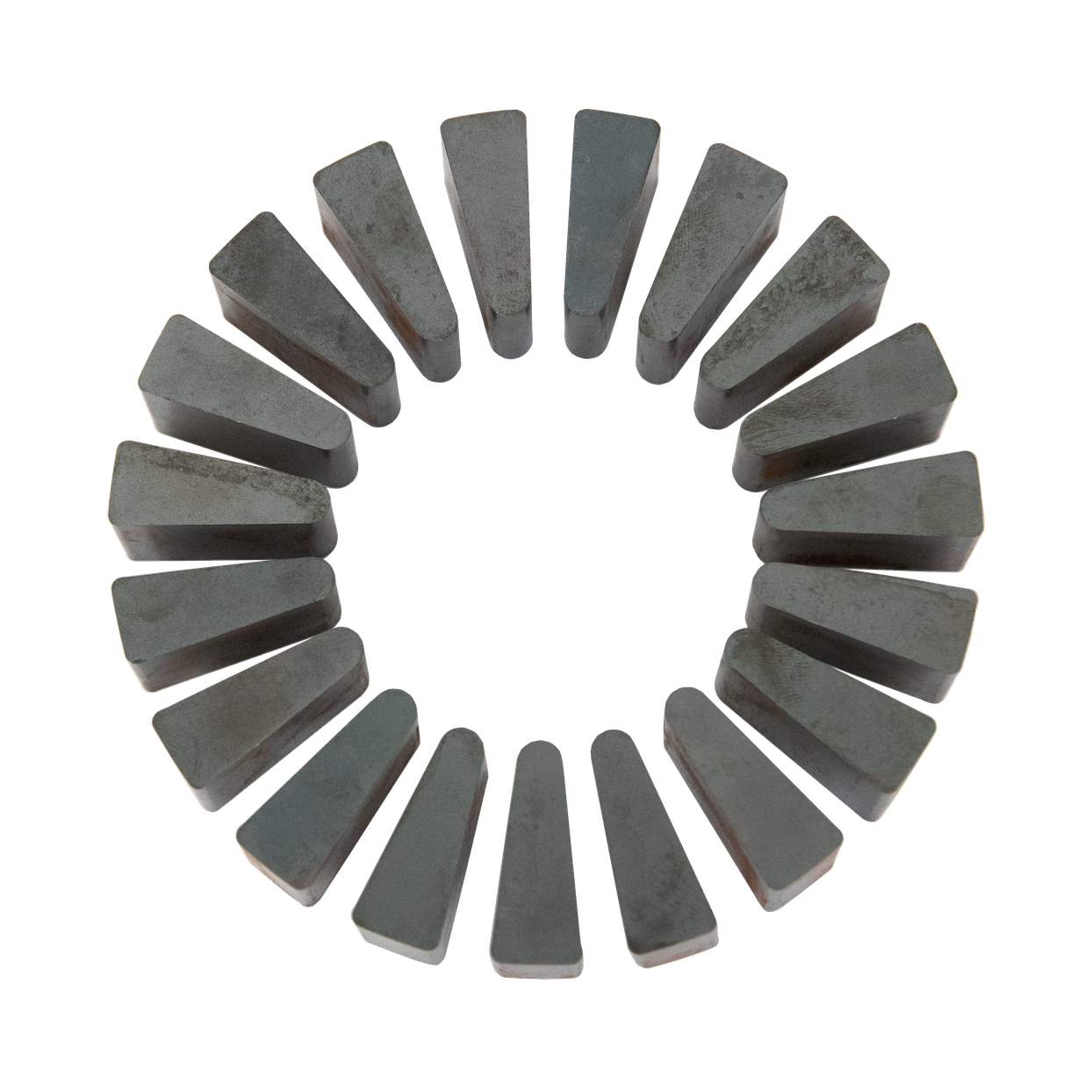

- Compact and Powerful: Our SMC materials enable the development of compact electric motors tailored to your specific requirements. The innovative 3D flux path allows design enhancement to improve power and efficiency. Moreover, innovative designs can potentially eliminate rare earth magnets thus reducing costs, giving you a competitive edge in the marketplace.

Solve Your Magnetic Performance Challenges with Sintered Soft Magnetics

Sintered Soft Magnetics (SSM) are engineered through advanced powder metallurgy to provide tailored magnetic properties and high performance, addressing the specific needs of diverse industries. Whether you’re developing DC magnetic devices or looking for reliable and cost-effective manufacturing solutions, SSM offers unparalleled versatility. With a range of materials including iron, silicon, and nickel alloys, SSM adapts to varying requirements in magnetic properties and structural strength, ensuring optimal permeability, saturation, and coercivity for your applications. Utilize our cutting-edge compaction technologies and high sintering temperatures to achieve superior magnetic performance, with permeabilities up to 7000, enhancing the efficiency of products like flux return paths, solenoids, relays, and motors.

Enhance Your Applications with Soft Magnetic Composites

Soft magnetic composites (SMCs) provide flexible solutions adaptable to numerous applications, enhancing performance in diverse industries including:

Discover How Our Solutions Transform Industries

Explore our diverse industry applications and see how our solutions drive success.

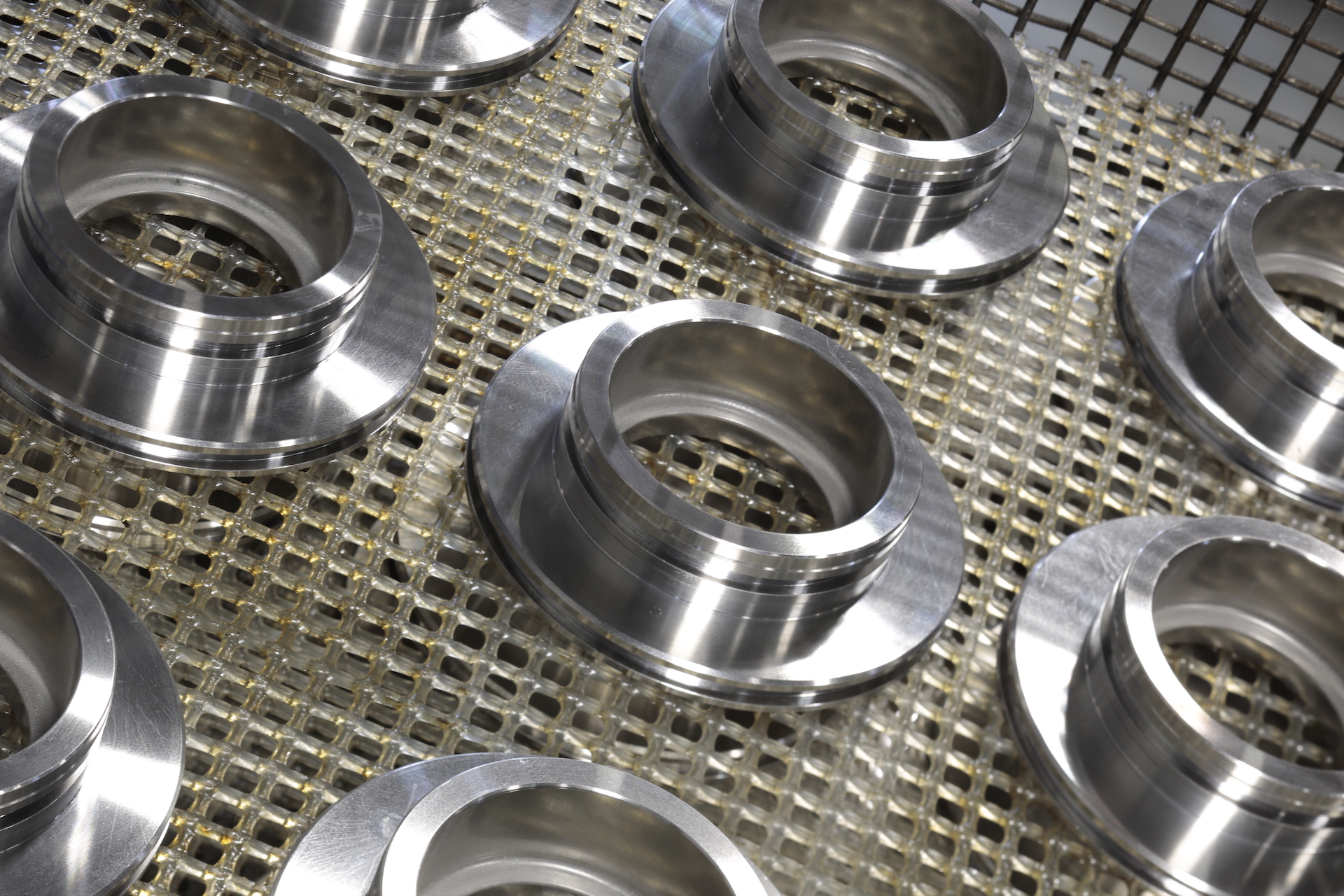

Soft Magnetics in Action

Resources

Soft Magnetic Composites Overview